Bodor Releases New U10 Pro Special Machine for Structural Steel Processing

On April 1, 2024, Bodor, a global leader in laser technology, launched its U10 Pro, a special machine designed exclusively for processing structural steel. Tailored for processing H-beams and I-beams, the Bodor U10 Pro provides a revolutionary manufacturing solution to effortlessly handle and streamline the multiple procedures of structural steel processing.

In modern construction, structural steel is a preferred material choice, offering advantages such as high strength, lightweight, and good durability. However, structural steel processing faces challenges with low efficiency, complex production procedures, high labor costs, and so on. With the vision to revolutionize customer experience, Bodor introduces the special profile laser cutting machine, U10 Pro, aiming to help manufacturers produce high-quality structural steel production with high efficiency and low costs.

Bodor U10 Pro key features

Bodor U10 Pro is the ultimate solution for all structural steel processing needs. With Bodor U10 Pro, gone are the days of tedious manual labor, and in comes the precision and efficiency of automation.

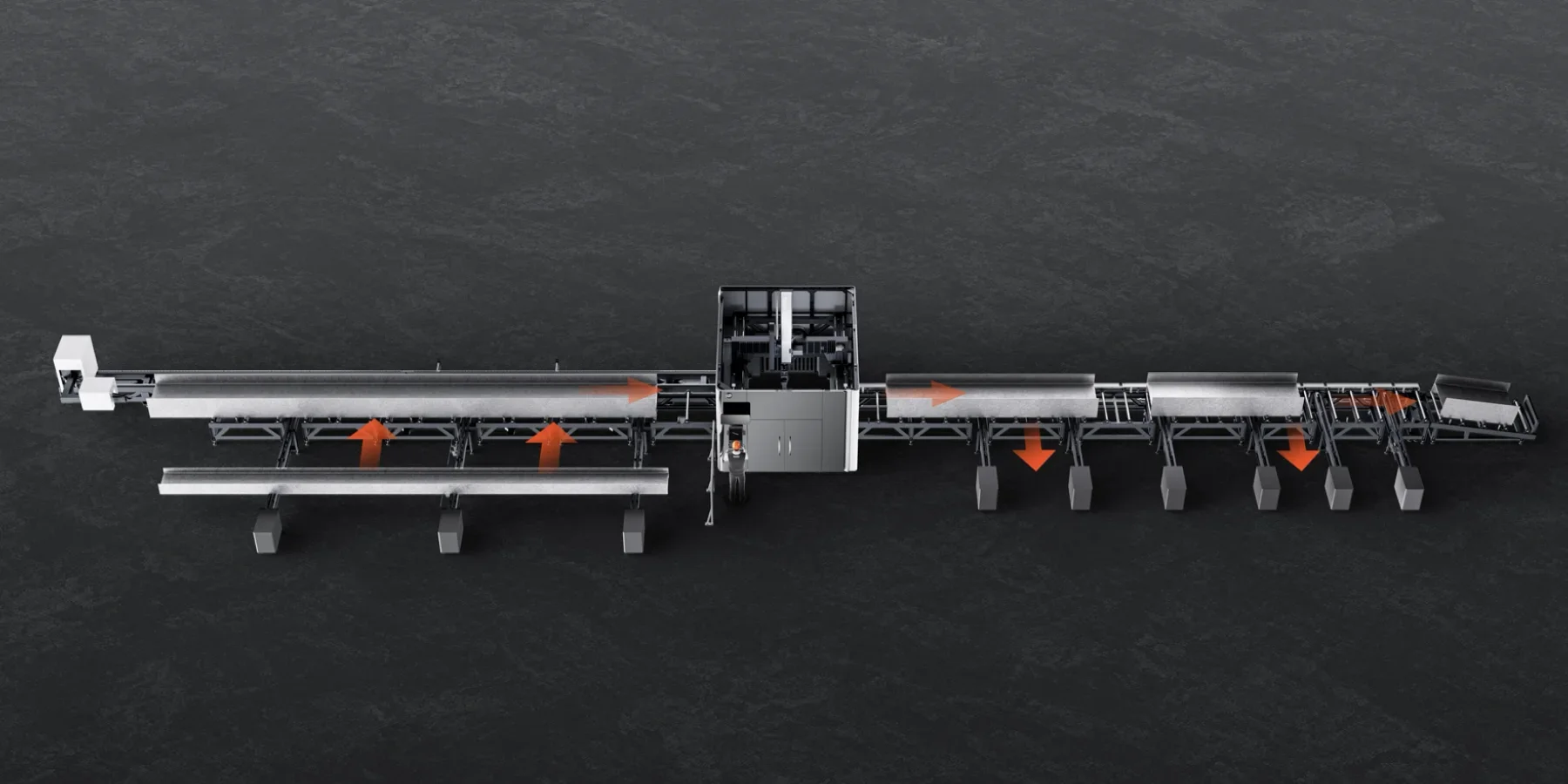

1.Integration of 6 processes

Bodor U10 Pro offers an all-in-one solution that seamlessly integrates auto-loading, punching, notching, beveling, cutting, and auto-unloading processes, boosting efficiency by an incredible 200%. The reliable and efficient machine can help you achieve your profile processing goals in the most efficient and cost-effective way.

(Automatic loading and unloading)

(Automatic loading and unloading)

2.Efficient notch cutting

With the laser head height adjustment feature, you can trust Bodor U10 Pro to get the notch cutting done perfectly in one go. It allows for precise and efficient notching, eliminating the need for manual polishing and doubling the efficiency.

(Locking notch in one operation)

3.Tekla compatibility

Bodor U10 Pro can be compatible with Tekla seamlessly, achieving one-click drawings component separation. Once the components are ungrouped, the software generates processing codes for the following operation. It provides a significant advantage in terms of streamlining the overall process, reducing errors, and improving the accuracy of the final output.

(Compatible drawings with Tekla)

(Compatible drawings with Tekla)

Strategic significance

"The introduction of the U10 Pro marks a significant milestone for Bodor," said Charles He, the Product Director of Bodor Overseas Marketing Center, "it is a specialized solution tailored for the structural steel industry. We firmly believe the new U10 Pro can help our customers enhance their productivity and competitiveness in the dynamic market. This powerful machine will also improve the overall efficiency of the structural steel supply chain."

The Bodor U10 Pro is an ideal option for manufacturers who prioritize efficiency, precision, and quality in their profile cutting procedures. With its state-of-the-art features and the remarkable 5-year warranty for three core components, Bodor U10 Pro represents our unwavering dedication to excellence and sets a new benchmark for the industry.

About Bodor

Founded in 2008, Bodor is an international top-notch intelligent and automated laser cutting and welding solution provider for automobiles, aviation, medical care, electronics, metal processing, and various industries. With more than 3,000 employees worldwide, including 20% dedicated to R&D, its service scope spans over 180 countries and regions. The global service centers and engineers provide customers with 24/7 timely support, maintaining long-term and stable partnerships with a variety of manufacturing enterprises.