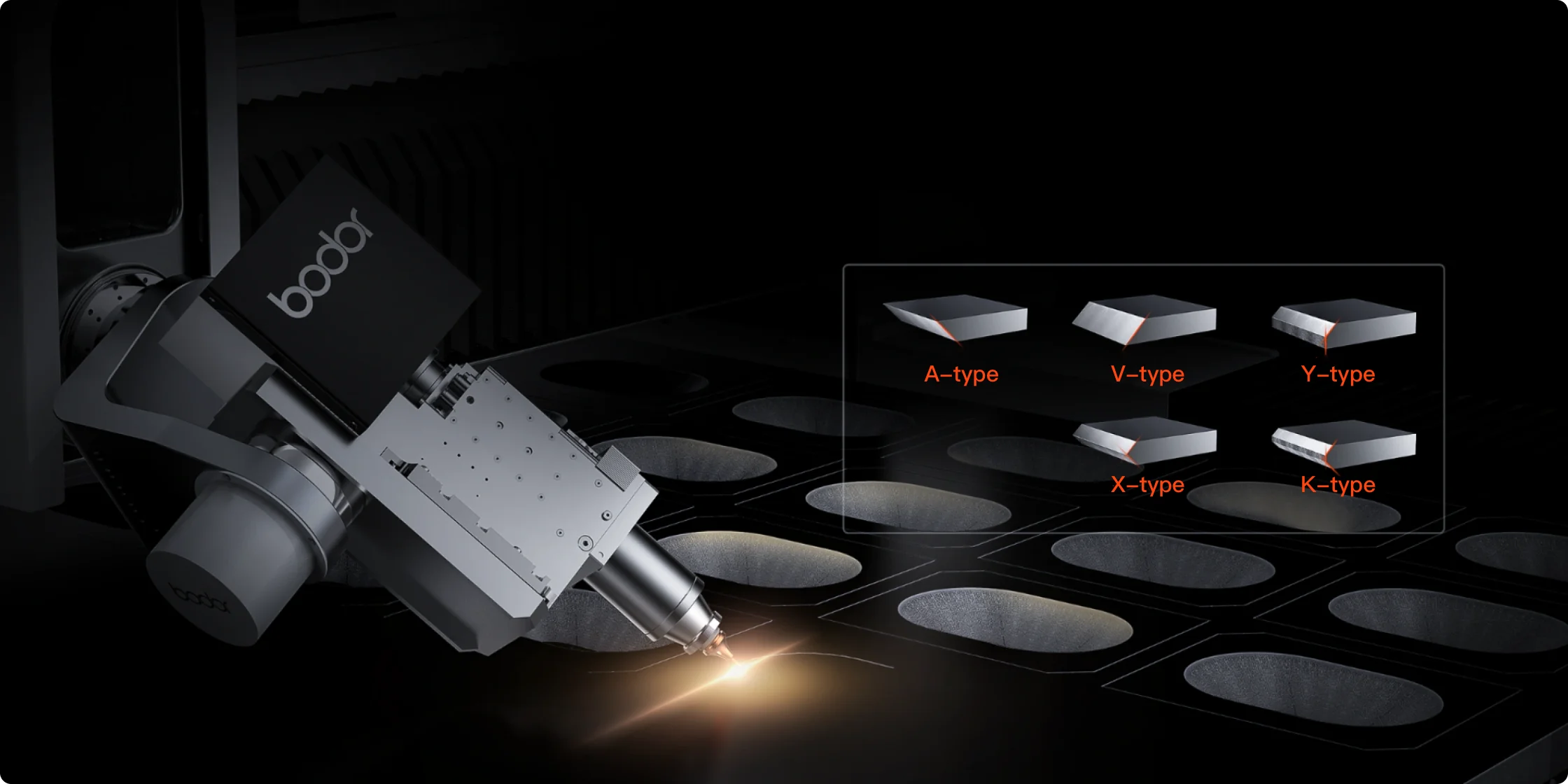

Request for samples to experience the precision cutting power of Bodor Laser

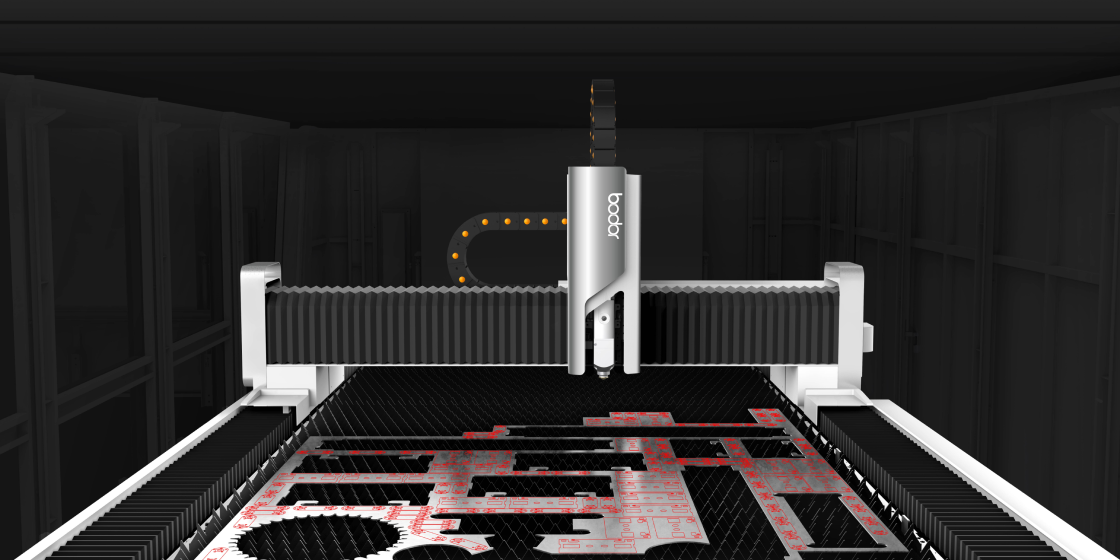

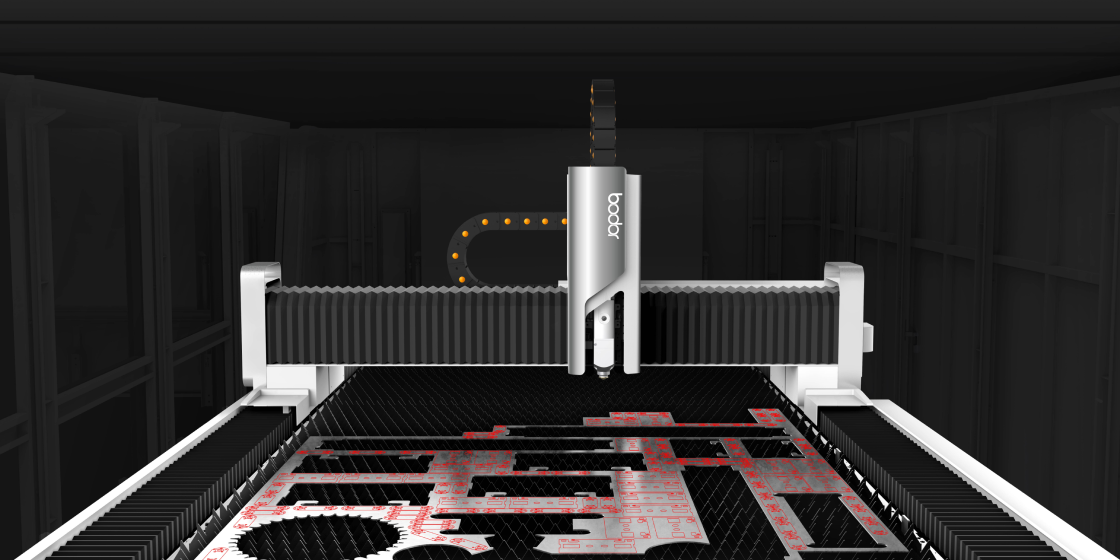

Schedule NowWith the protective enclosure, the C Series delivers you peace of mind, ensuring maximum safety of operators.

The 3rd-generation mortise-and-tenon bed frame and mineral cast anti-burn plate extend the machine's life greatly.

With smart cutting parameter auto-match and remnants layout, the C Series simplifies the operation.

It adopts high-performance bus servo motors to achieve the absolute leading dynamic performance

(compared with similar products in the market).

Significantly improving processing efficiency to ensure that every second you invest is creating

value.

Maximum acceleration up to

Overall Performance

Note: The "Overall Performance Improved by 30%" mentioned above is relative to Bodor's previous-generation product.

*Optional for C12

Regardless of whether you require general advice or specific support, we are happy to help you.