Power Your Way Up

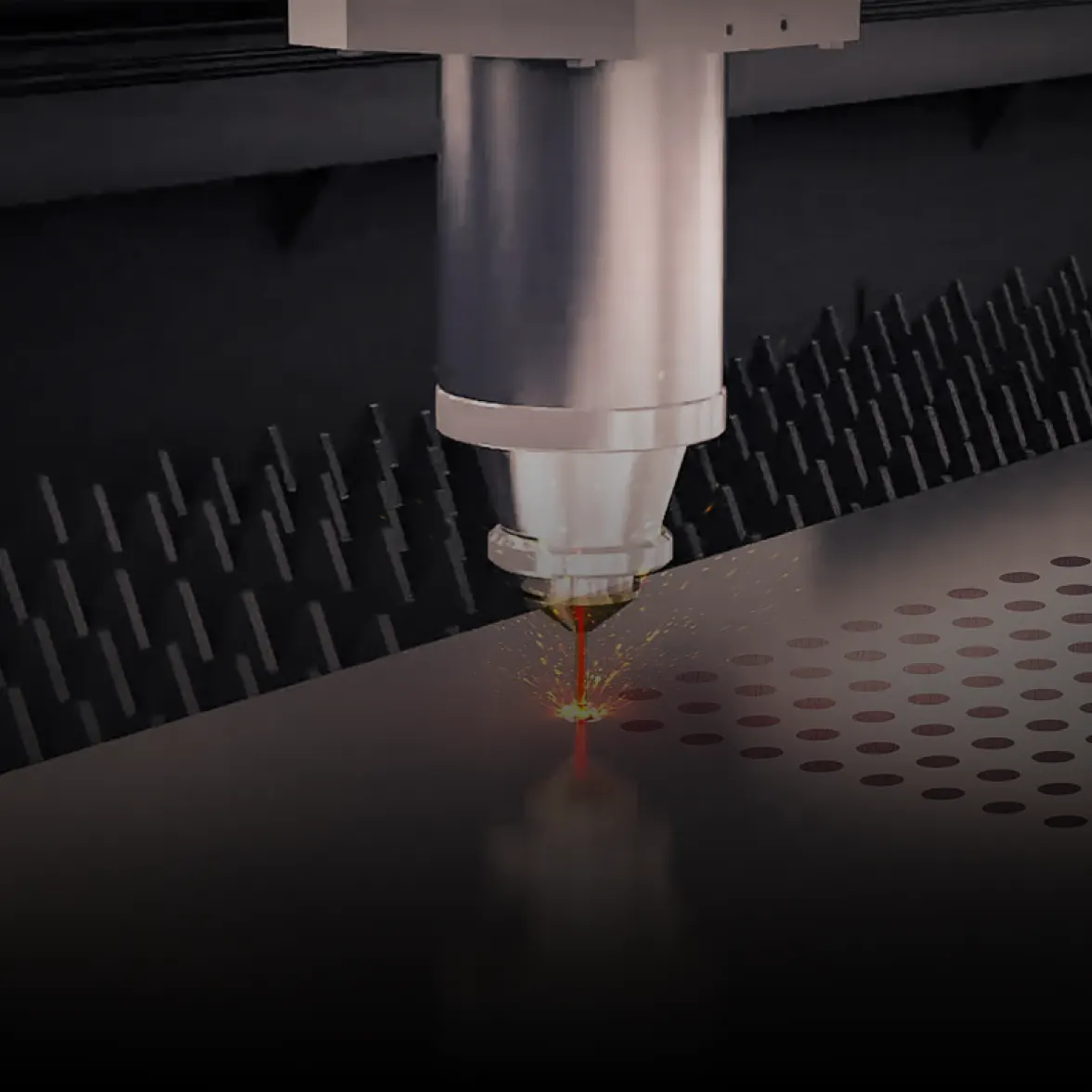

With Bodor 10kW+ high power level fiber laser cutting machine

Request samples

Get a quote

ROI esitimation

Why high power level laser cutters ?

Boosted cutting speed

Cut through thick materials at much faster speeds, reducing production time and increasing output for improved cutting processes.

Improved cutting quality

Cleaner, sharper cuts with minimal slag, distortion or heat-affected zones, resulting in higher quality finished products.

Enhanced versatility

Greater amount of energy per unit area and improved beam absorption to efficiently cut through a wide range of materials and thicknesses.

Increased cost-effectiveness

Less energy required for high power lasers to cut through thicker materials with lower operating costs and machine maintenance costs thanks to longer lifespan of machine.

10kW+ high power laser - the perfect solution for various fabrication needs

Discover the core technologies that make Bodor high-power laser superior.

Automatic follow-up height adjustment

Automatic follow-up height adjustment

Automatic system to monitor and adjust the laser head height according to the temperature and rust conditions of the material surface.

Consistent and accurate piercing and cutting performance, even for large-format plates.

Simple to use, durable and compatible with various types of thick plate materials.

BodorThinker self-developed control system

BodorThinker Self-developed control system

BodorThinker is a high-end intelligent control system for a CNC laser cutter, featuring reliable stability, convenient installation and adjustment, safe production, multiple functionality, and robust performance. With BodorThinker, your laser cutting solutions can be modular, customized, automated and information-based.

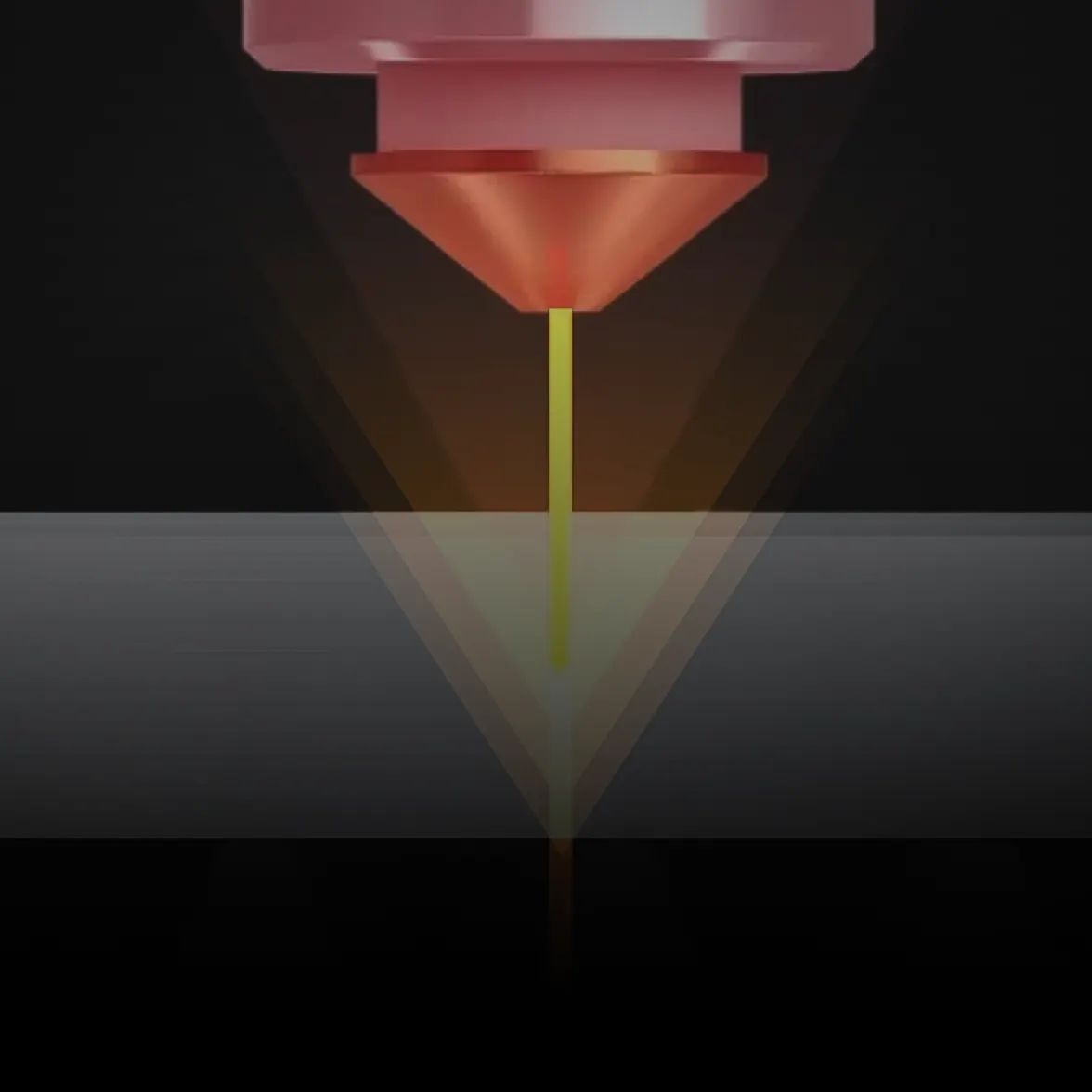

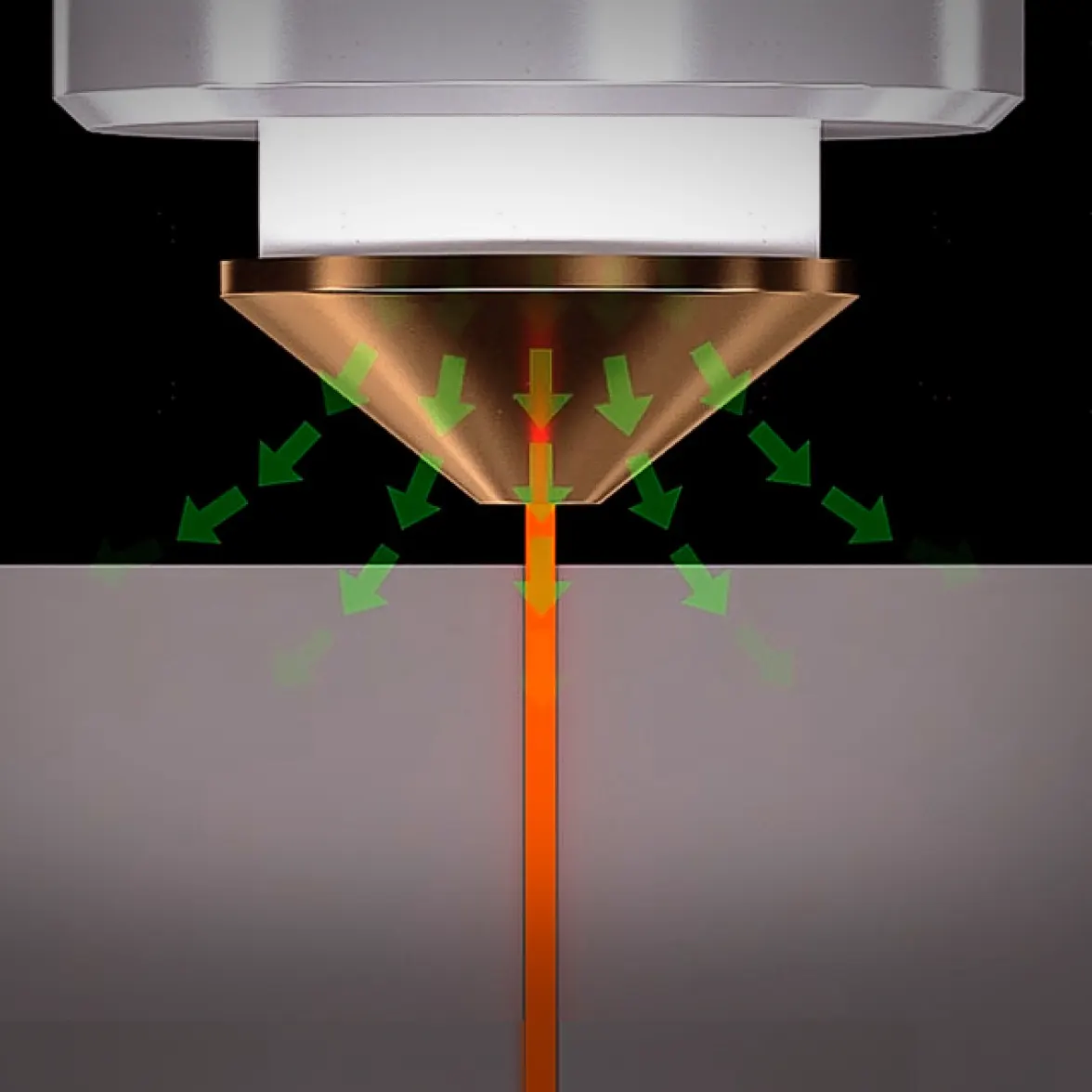

Multi-level piercing + intelligent piercing

Multi-level piercing + intelligent piercing

Instant piercing in medium-thick plates.

Stable piercing and cutting in ultra-thick plates.

Improved piercing stability during processing of large format ultra-thick plates.

Thick plate cutting overheat compensation

Thick plate cutting overheat compensation

Automatic adjustment in real-time based on cutting duration.

Troubleshooting unstable cutting results during long-duration laser cutting.

Bodor 10kW+, the preferred choice of 3,000+ customers across the globe

Client’s success story

Discard the plasma cutting machine and upgrade to 22kW high-power laser, a Swedish grapple manufacturer reaps high precision & superior cut quality.

8x

Precision increased

98%

Products with taper deceased

100%

After-sales service satisfaction

“Our P6 laser cutting machine has been running for 6 months, and we are more than satisfied. Besides the powerful machine itself, Bodor’s warm and professional after-sales service pleasantly surprises us the most. They have skilled experts who set the equipment and cut parameters properly for us and are always very fast to respond. They also own sufficient spare parts for any in-need occasions. Thank Bodor for such a great service experience!”

Magnus Faxbrink

Plant Manager of HSP Gripen

Applicable industries

Metal fabricating

Architecture & construction

Shipbuilding

Automotive

Railway bridge

Agricultural machinery

Request samples

Get a quote

ROI esitimation

Get a Quote

At Bodor Laser, we evaluate your cutting requirements and offer free consultation service on a case-by-case basis. If you require further suggestions, please fill out the form to contact our sales experts.