24kW & 30kW Ultra-High-Power Laser

Stay competitive in the rapidly changing manufacturing industrie

Request samples

Get a quote

ROI esitimation

Common challenges with lower power lasers:

Limited cutting capabilities

Lower power lasers struggle to cut through thicker materials (above 16mm), resulting in slower production times and reduced output.

Reduced precision

As material thickness increases, lower power lasers may produce less accurate cuts, negatively impacting product quality.

Higher energy consumption

Lower power lasers often require multiple passes to cut thicker materials, consuming more energy and increasing operational costs.

The advantages of 24kW & 30kW ultra-high-power lasers

Increased cutting speed

If your business is grappling with metal thicknesses ranging from 16mm to 40mm, the cutting techniques offered by the 24kW and 30kW machines will work like magic in your plant. Not only will they greatly enhance your productivity, but they will also enable you to meet the demands of your clients more effectively.

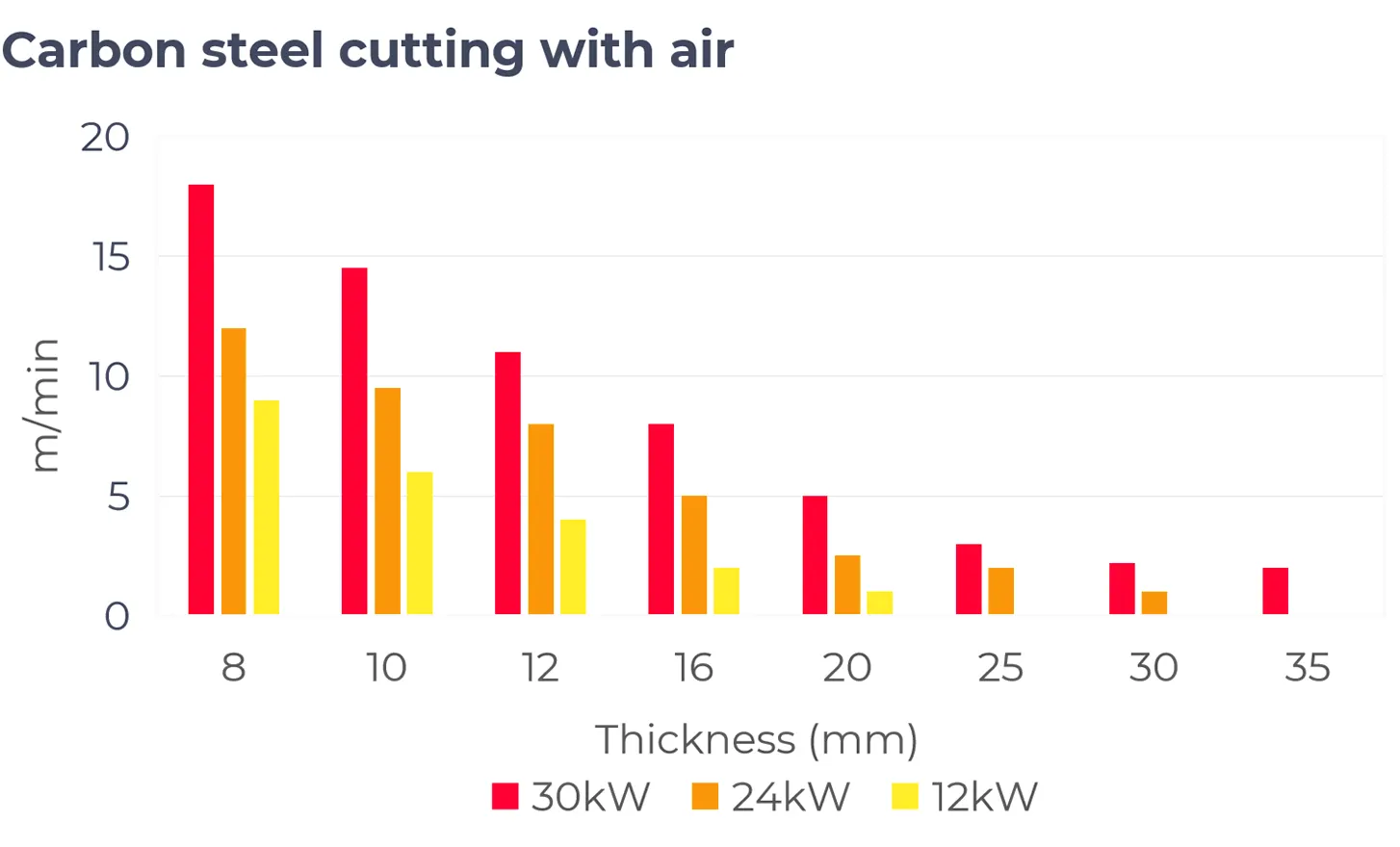

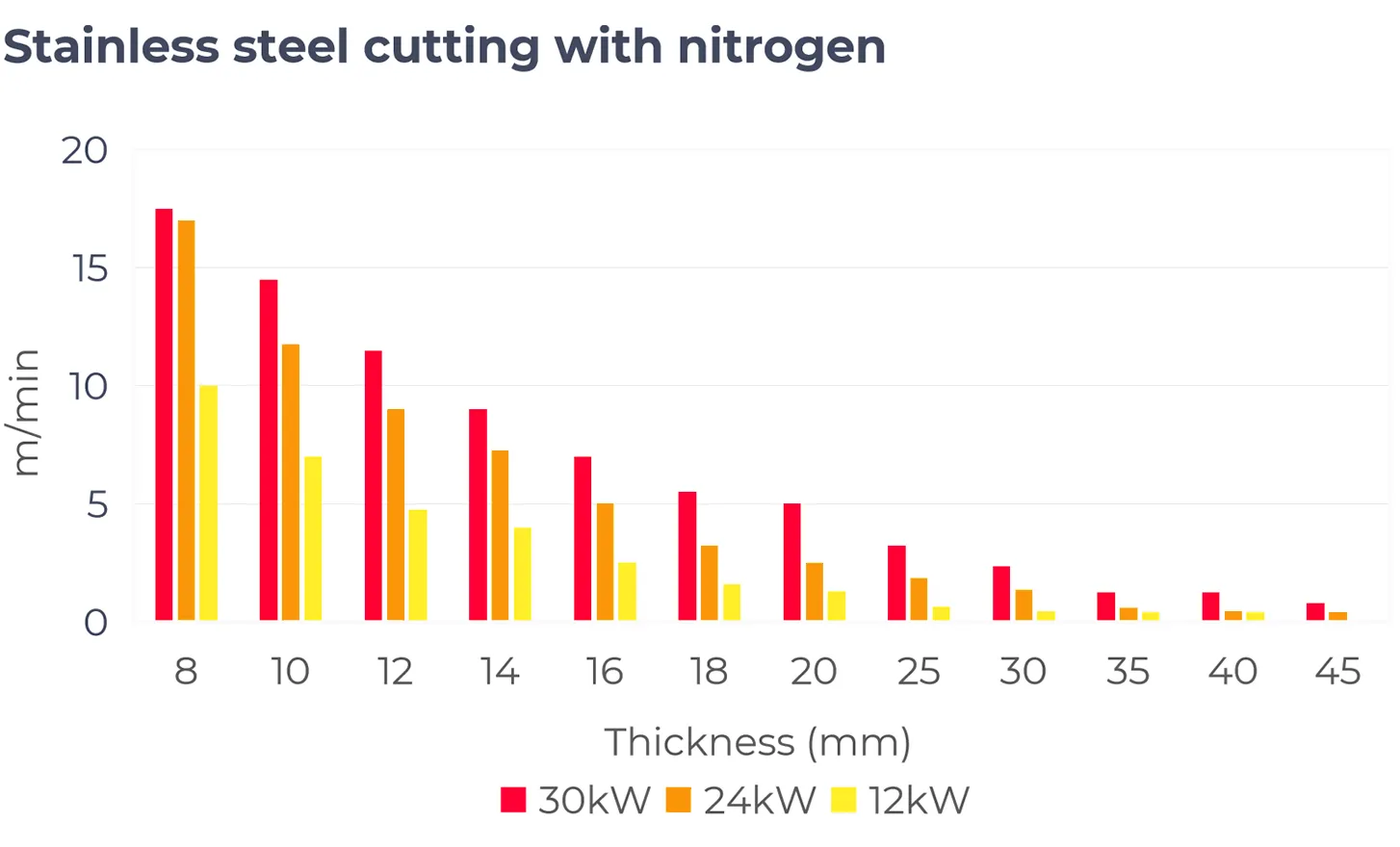

Cutting speed comparison of 12kW, 24kW, and 30kW

24kW and 30kW allow you to complete jobs faster and serve more clients.

*The data are lab-measured by Bodor.

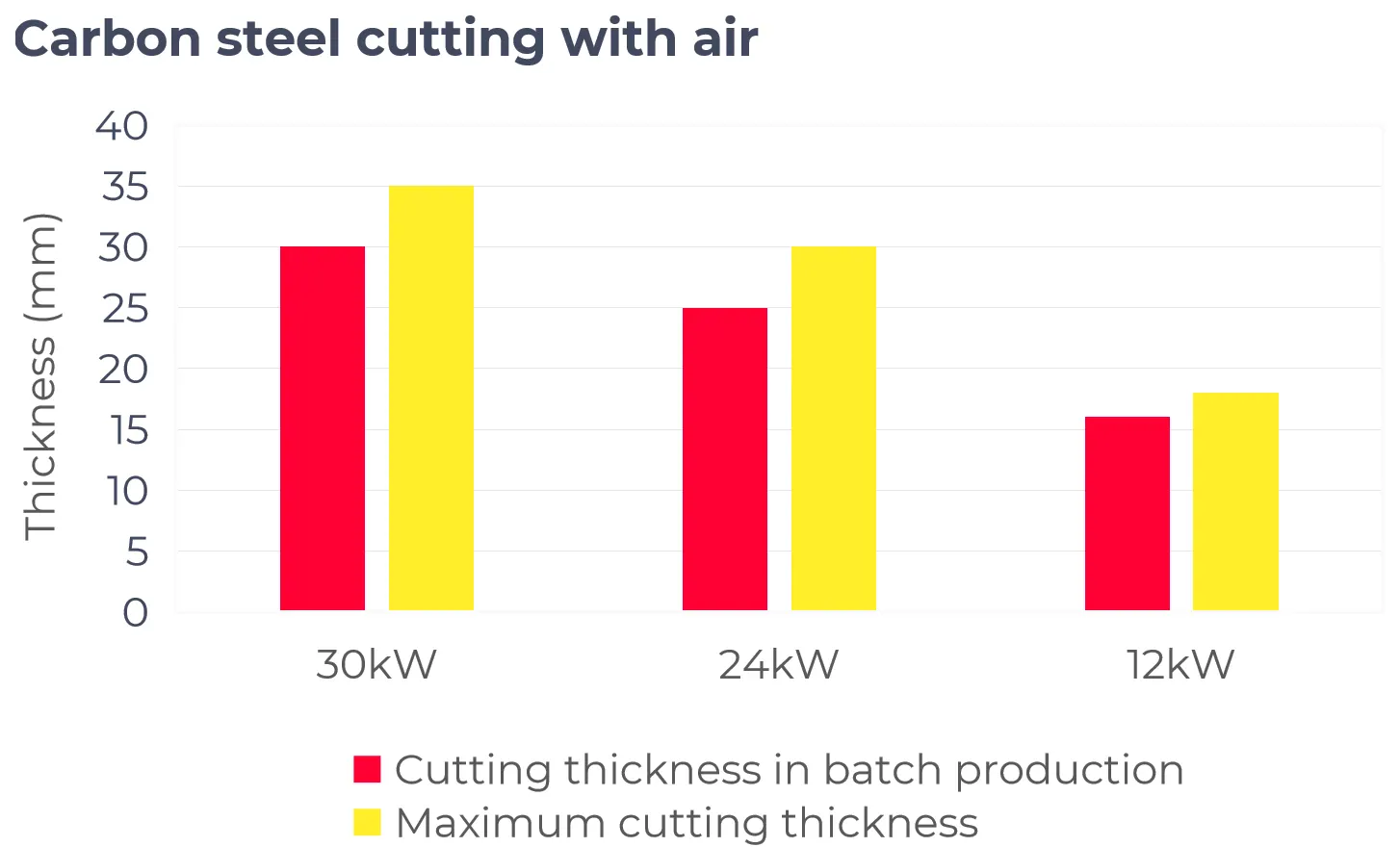

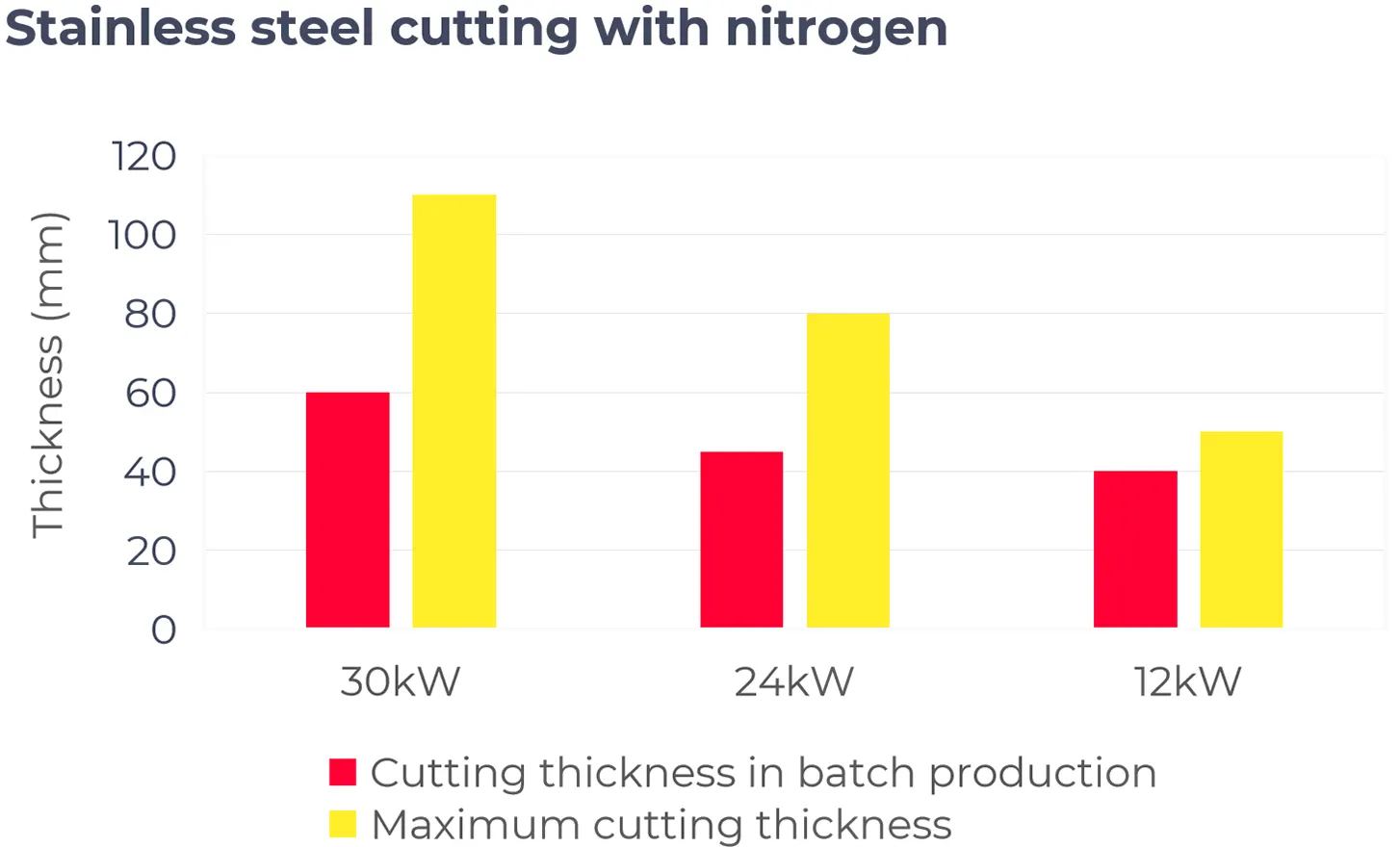

Exceptional thickness capacity

24kW and 30kW lasers are capable of cutting thicker materials, including both carbon steel and stainless steel. This increased capacity allows you to serve a more diverse clients and take on more complex projects. Choosing these powerful lasers will enable you to stay competitive in the industry and elevate your profits.

Maximum cutting thickness comparison of 12kW, 24kW, and 30kW.

24kW and 30kW enable you to tackle a broader variety of applications.

*The data are lab-measured by Bodor.

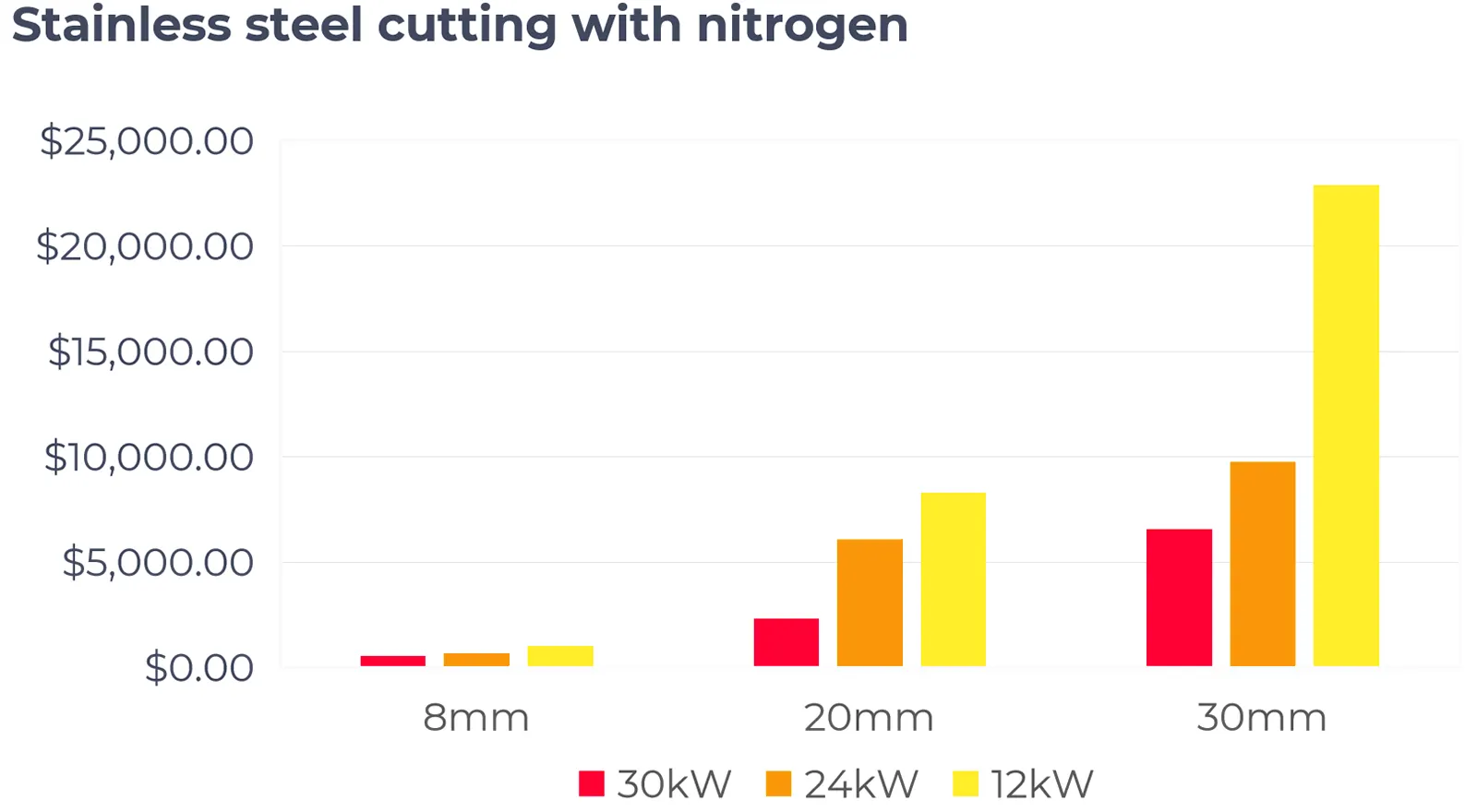

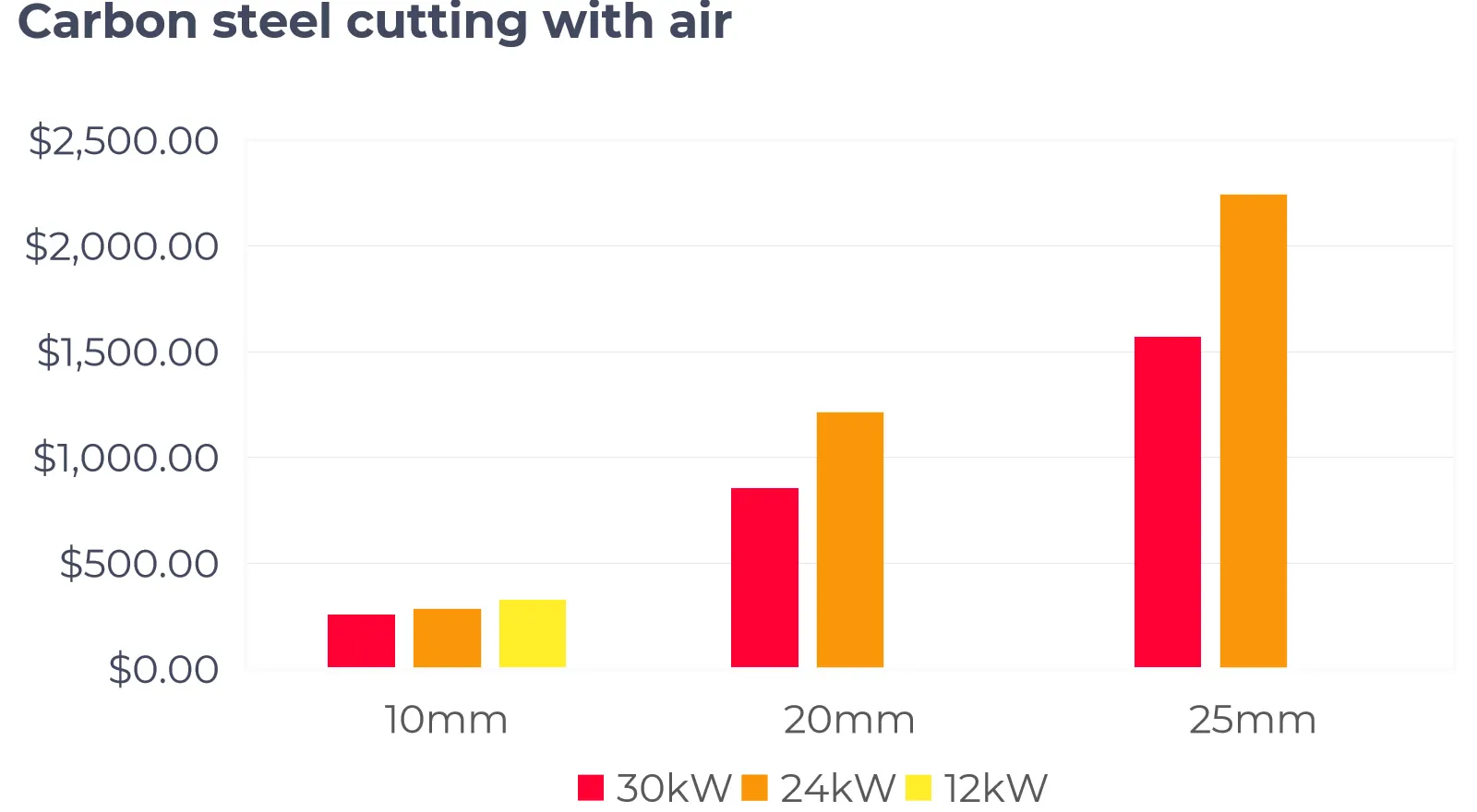

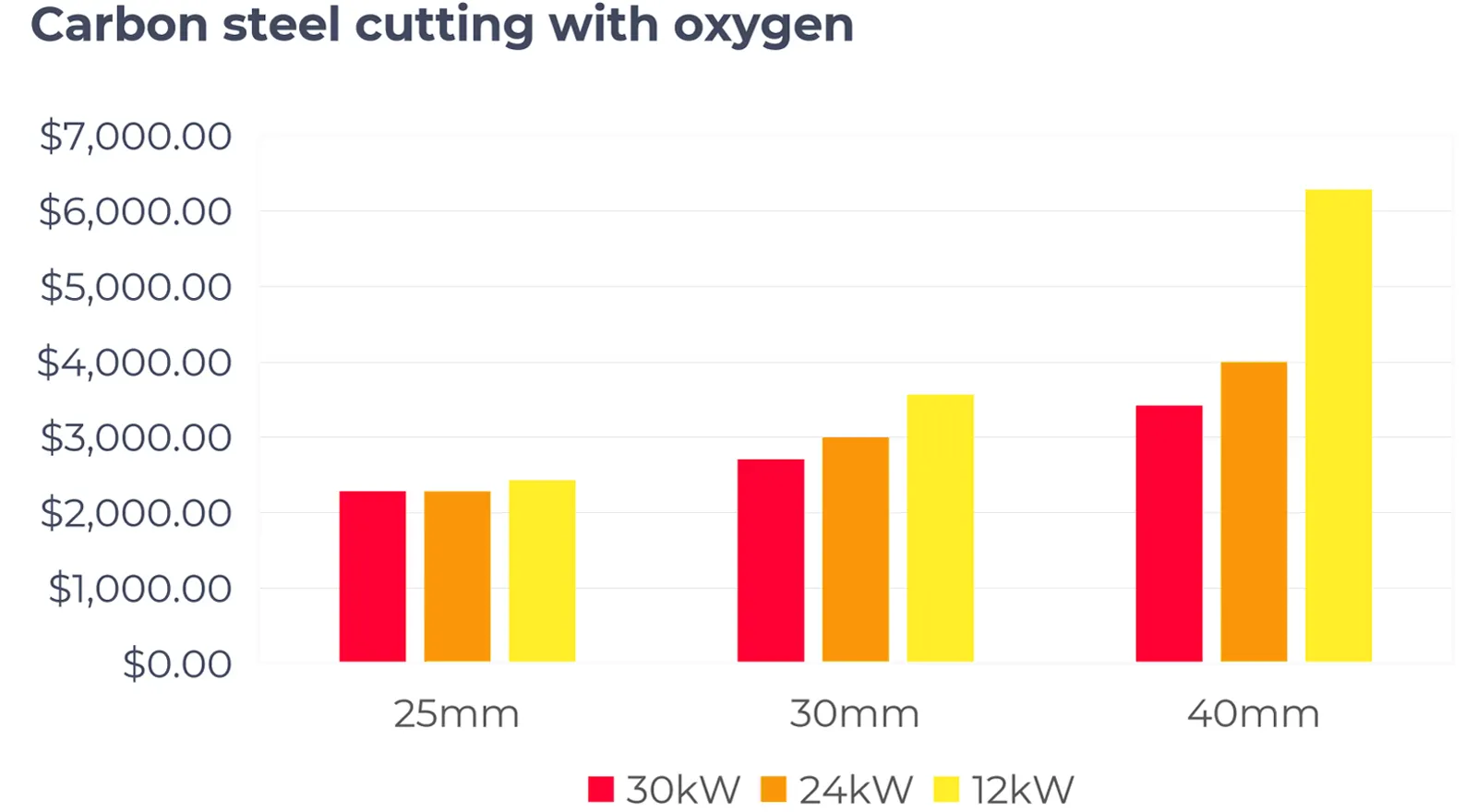

Remarkable cost efficiency

24kW and 30kW devices deliver monthly costs for cutting different materials and thicknesses compared to the 12kW. And the savings increase as the thickness range expands. By investing in a higher-power laser, you can enjoy 15-70% cost savings for thick plate cutting while increasing your production capabilities.

Monthly Operational Costs Comparison for Cutting 10,000 Meters with 12kW, 24kW, and 30kW

24kW and 30kW provide significant savings in the long run.

*The data are lab-measured by Bodor.

Applicable industries

Agricultural machinery

Architecture & construction

Railway bridge

Auto parts

Shipbuilding

Metal fabrication

Client’s success story

Optimal solution to enhance efficiency and upgrade business

67%

Cutting time reduced

2x

Cutting capability

87%

More efficiency

Besides the amazing machine of Bodor, the technique support from their skilled technicians is really professional and fast. And they offered free training when our machine arrived, which was indeed helpful for us and let us start using the laser cutter quickly. With Bodor’s high power machine, we aim to increase speed, improve quality, and reduce costs to generate better margins. We strongly believe that Bodor can help us achieve this goal

Remco Nauta

Director and owner of Snijbedrijf Nauta B.V.

Request samples

Get a quote

ROI esitimation

Get a Quote

At Bodor Laser, we evaluate your cutting requirements and offer free consultation service on a case-by-case basis. If you require further suggestions, please fill out the form to contact our sales experts.