Bodor’s Innovation of Scanning Laser Cutting Technology Unveils the Secret to Efficiency at Global Industrie 2023

Lyon, France, Feb. 28, 2023 / -- Bodor Laser, a leading provider of laser cutting solutions, is pleased to announce that it will be showcasing its cutting-edge laser cutting solutions, including its new scanning cutting feature, at the Global Industrie trade show from March 7th to 10th at the Eurexpo exhibition center in Lyon, France.

Bodor's participation at Global Industrie 2023 will feature the P3 12kW all-around sheet fiber laser metal cutting machine and T230A 3kW all-around fiber laser metal tube cutting machine. One of the highlights of Bodor’s showcase at the show will be the in-action demonstration of Bodor scanning cutting, a new technical innovation applied to the P3 12kW model.

(Bodor T series)

Hailed as a new laser equipment category creator since its first global debut in 2022, Bodor scanning laser cutting technology is innovated to tackle the long-existing pain points in the metal fabrication and laser cutting industry, such as poor processing efficiency of non-ferrous metal, laser damage due to the beam from the highly reflective material batch process, and limited output power of laser cutting equipment.

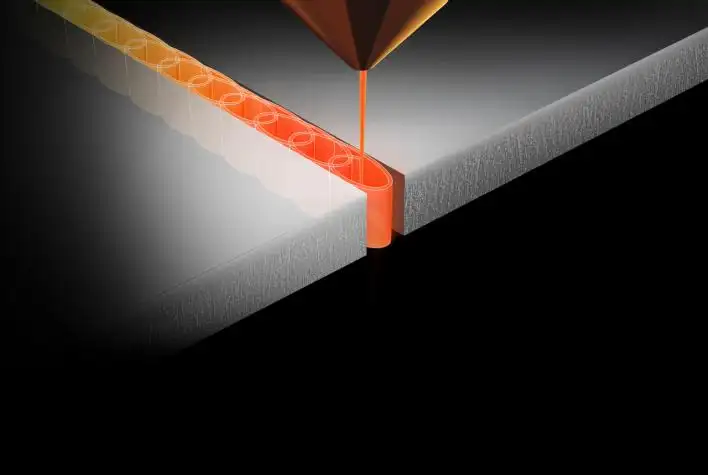

With an optical system device, optical path spatial programming technology, and patented process algorithm, scanning cutting enables a significant increase in cutting material thickness with the same machine power band and delivers a substantial enhancement in cutting speed with the same machine power band and material thickness.

The secret to the unparalleled efficiency of Bodor scanning cutting lies in dynamic spot cutting with the spot traveling 30 meters for every 1-meter cut, which significantly increases the efficiency of the laser energy absorbed by the material being processed, in contrast to static spot cutting.

Amelie Yu, the regional sales manager (France) of Bodor Laser, said, "Compared with conventional laser cutting machines, the same power laser scanning cutting machine achieves a cutting thickness increased by 100% and cutting speed increased by 180%. Scanning cutting as a new technical feature makes Bodor’s laser cutting solutions a real game-changer in processing thick and highly reflective materials at impeccable speed with minimized costs for our customers.”

About Bodor

Founded in 2008, Bodor Laser is a world-leading intelligent laser solutions provider, specializing in the manufacturing, research, and development of laser cutting equipment headquartered in Jinan, China. With the mission to "Change human life with laser technology", the company is committed to driving the innovation of laser cutting technology, fostering sustainable growth in the manufacturing industry, and providing the premier laser cutting solutions to customers across the globe. We boast our star machine models across flagship, performance, and economic series with comprehensive coverage of machine power bands from 1000W to 50000W.