Bodor Tech Blog

Trending and helpful laser knowledge for your success

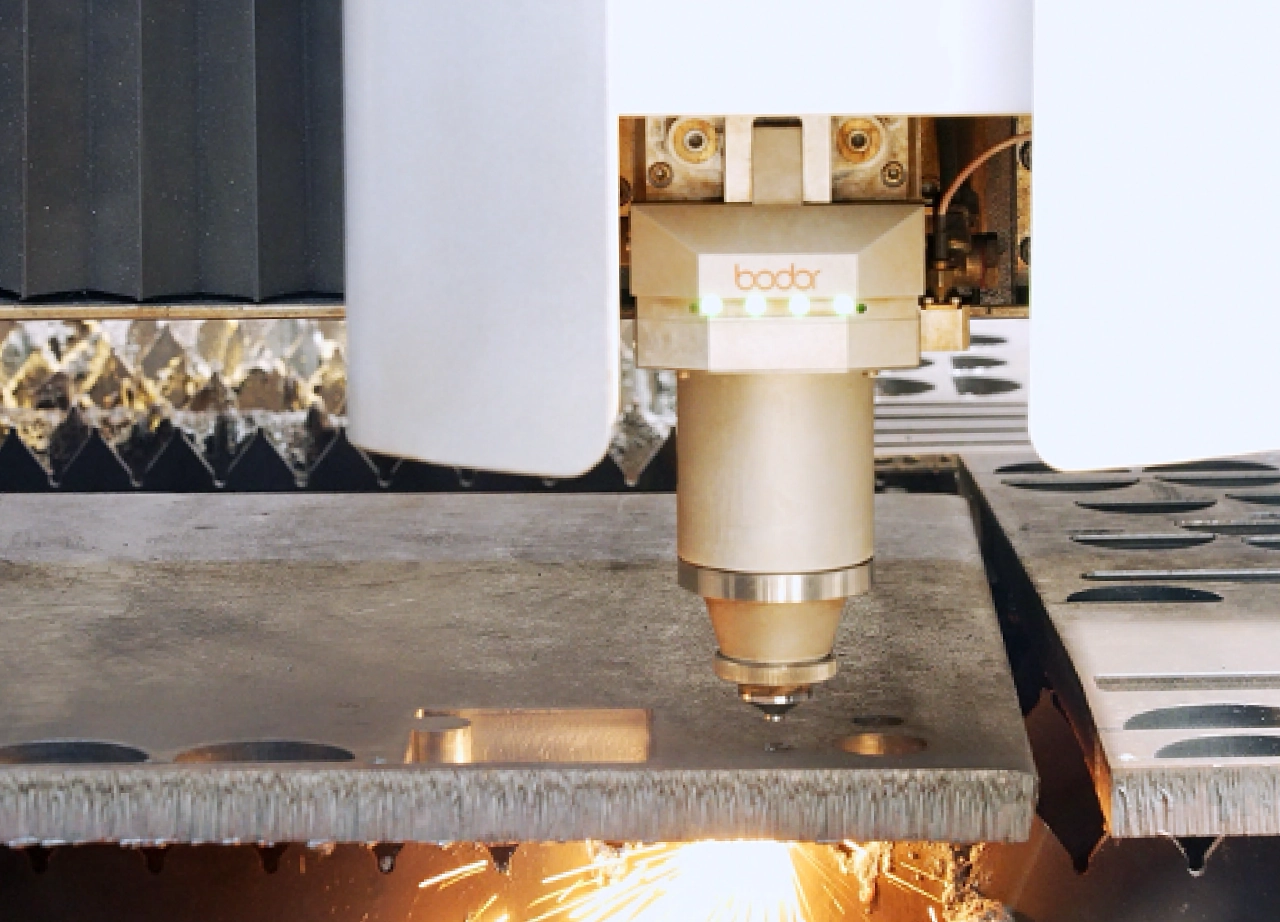

Bodor Intelligent Cutting Application - Intelligent Gas Pressure Control

As the quality of laser source and laser head is gradually stabilized, the auxiliary gas pressure has become the most difficult part to control in the cutting process. The small difference of gas pressure directly affects the cutting quality.

According to statistics, the maintenance resulting from adjusting cutting parameters accounts for 30% of all faults, and 40% of these maintenance is related to auxiliary gas.

The importance of gas pressure control is now taken for granted.

1. What is gas pressure control?

As we all know, the ideal laser cutting speed and cutting surface need five main factors: appropriate laser source power, laser head focusing, appropriate auxiliary gas pressure, appropriate cutting height and appropriate nozzle model.

The laser power can be monitored by software which guarantees that the actual value is generally equal to the set value, and the power is relatively stable. Similarly, the hardware and focus of the laser head can be monitored by software as well. However, the actual gas pressure at the nozzle is smaller than the set gas pressure. The actual value depends on many factors, such as loss in the pipeline between the proportional valve and the laser head, the difference of the proportional valve, the nozzle diameter, voltage and so on.

Bodor Intelligent Gas Pressure Control refers to controlling the gas blowing in the machine tool. The detection module on the laser head will monitor the gas pressure at this position, and the system will calibrate and compensate the gas pressure at this time to keep the gas pressure blown by the cutting nozzle consistent with the set value.

According to Bodor customer service engineers, they found in the practical customer service that when many customers were aware that the cutting surface of the equipment was poor, the cutting speed was slow, or even unable to cut, it was often caused by abnormal cutting gas pressure parameters. For example, when the configuration of laser and laser head of the same model are the same, although the cutting speed is similar, the cutting parameters are quite different.

2. Economic benefits brought by Intelligent Gas Pressure Control to our customers

-The reproducible rate of cutting parameters of the same model and configuration model is increased from 50% to 90%.

-The maintenance rate caused by replacing different batches of nozzles, which leads to bed cutting section, has been reduced by 80%.

-It solves the problem of poor cutting after users replace the proportional valve.

-The cutting stability is increased, the operation threshold of customers is reduced, and the maintenance rate caused by gas pressure problems is reduced by 40%

Now the Intelligent Gas Pressure Control function is applicable to all Bodor laser cutter models with 12kW, 22kW, 30kW, or 40kW.