Bodor Tech Blog

Trending and helpful laser knowledge for your success

6 Questions Successful Auto Parts Manufacturers Ask Before Choosing a Laser Cutting Solution in 2023

In 2023, the automotive parts manufacturing industry is experiencing significant growth opportunities, but it also faces increasingly fierce competition.

This industry comprises businesses specializing in the production of motor vehicle components and accessories, excluding the manufacture of engines, engine components, batteries, and vehicle bodies and chassis.

However, these manufacturers play a crucial role throughout the entire automotive manufacturing process.

They typically supply components and accessories to original equipment manufacturers (OEMs) for the production of complete vehicles or provide replacement parts to OEM dealers, as well as supply parts to the aftermarket.

Yet, the automotive parts manufacturing industry is confronted with substantial challenges and opportunities.

Global supply chain issues, the proliferation of electric vehicles, trends in automotive intelligence, and evolving regulations are profoundly altering the landscape.

Meanwhile, automotive parts manufacturers must contend with commodity price fluctuations and evolving regulations.

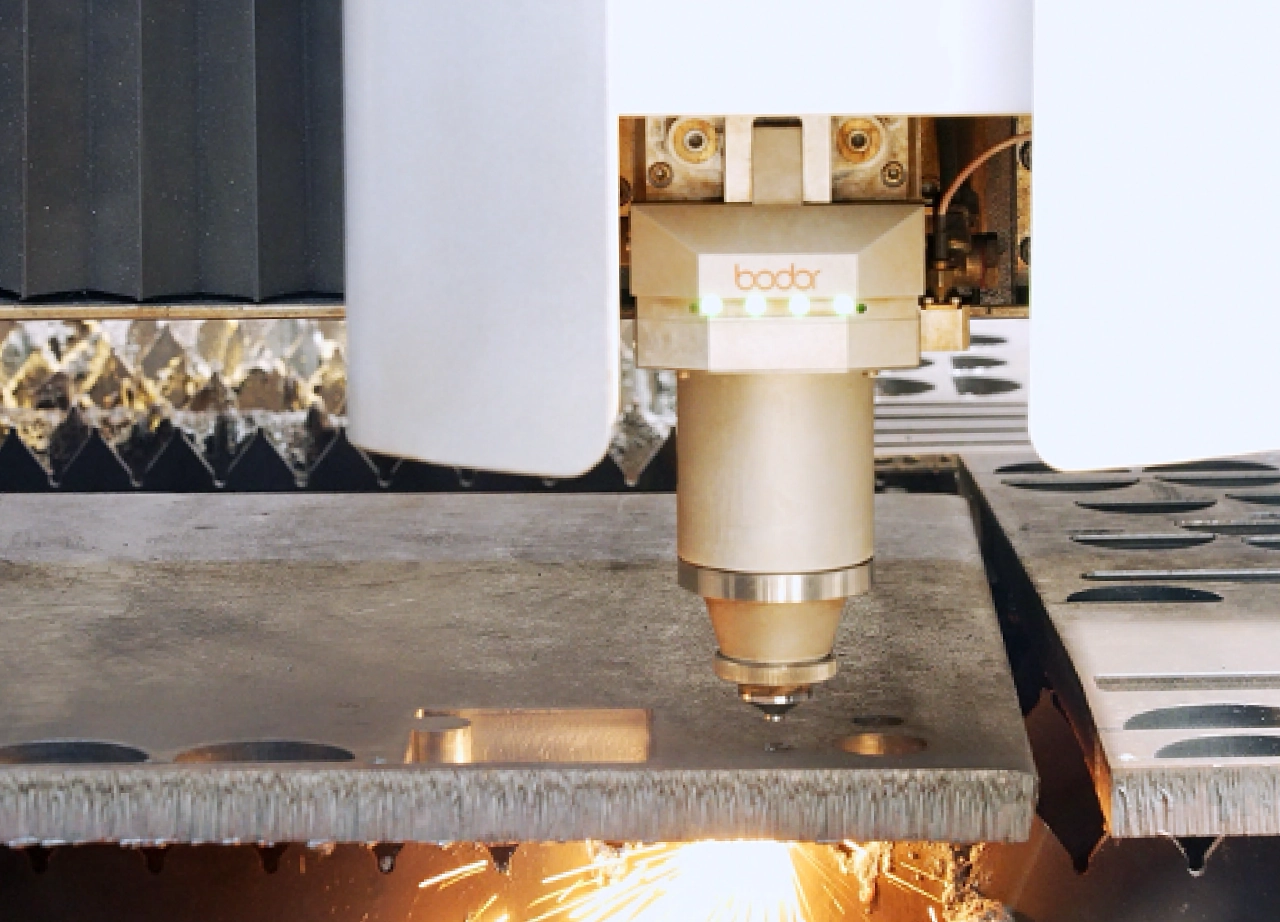

At this transformative moment, successful auto parts manufacturers are turning their attention to a revolutionary technology: laser cutting.

This technology not only enhances production efficiency but also enables high-precision, high-quality manufacturing.

However, before choosing a laser cutting solution, manufacturers need to address these six key questions:

1. Is My Auto Parts Product Suitable for Laser Cutting?

This question requires careful consideration of your product type and requirements. Laser cutting is suitable for various materials, including carbon steel, stainless steel, aluminum, brass, and copper, but material thickness must be taken into account. If your product primarily consists of carbon steel under 20mm thick or stainless steel under 10mm thick, laser cutting is often an ideal choice. This multi-material, multi-functional cutting technology provides manufacturers with greater flexibility, allowing you to process different types of parts and perform various processes on the same machine.

2. What Type of Laser Cutting Solution Do I Need?

Different production requirements call for different types of laser cutting machines. For example, if you need high-speed cutting to meet large batch orders, high-power 10kW+ laser cutting machines might be your top choice. If your products require higher precision and smoothness, high-performance laser cutting machines may be more suitable. For manufacturers specializing in producing complex, three-dimensional, and thermoforming automotive parts, investing in a more advanced solution like a three-dimensional, five-axis laser cutting machine can be the best course of action. Selecting the right machine type directly impacts product quality and production efficiency.

3. How Do I Ensure Laser Cutting Quality?

Quality is paramount in automotive parts manufacturing. The quality of laser cutting depends on multiple factors, including machine performance, maintenance, and operation. High-quality laser cutting machines ensure the accuracy of component dimensions and shapes, reducing the need for subsequent processing and enhancing quality. Additionally, regular maintenance and operator training are key to maintaining high-quality production.

4. How Can I Improve Production Efficiency?

A competitive market demands that manufacturers improve production efficiency. Laser cutting machines offer rapid cutting speeds and efficient processing capabilities, allowing for the completion of a large volume of work in a short time. Combining laser cutting machines with automated production lines can reduce manual intervention, increase efficiency, and save time and costs. Furthermore, advanced features like marking, flying cutting, and countersink can expedite the production process.

5. How Can I Meet Environmental Requirements?

Environmental consciousness is rising globally. Laser cutting technology is relatively eco-friendly because it doesn't require the use of chemicals and doesn't generate emissions, wastewater, or waste residues. This not only reduces environmental impact but also makes your products more environmentally compliant, enhancing your brand's reputation. Choosing laser cutting also means reduced reliance on traditional energy sources, resulting in lower energy consumption during production.

6.What Are Feasible Investment Costs and Return Periods?

Introducing laser cutting technology involves capital investment. However, the advantages of laser cutting lie in improved production efficiency and product quality, as well as the potential for creating new market opportunities. Therefore, you need to carefully assess investment costs and consider the expected return period. In most cases, the efficiency and versatility of laser cutting machines enable them to achieve a relatively short return on investment.

In Conclusion

Laser cutting technology offers unique advantages to automotive parts manufacturers, including high precision, high quality, efficiency, and environmental friendliness. By thoughtfully addressing and answering these six questions, manufacturers can wisely choose laser solutions that meet their business needs for sustainable success.