Transferring from Outmoded Plasma Cutter to Bodor Laser Scanning Cutting Technology

A U.S. Sheet Metal Fabricator Employs Bodor A3 Model to Increase Efficiency and Reduce Labor Expenses

The Company's Success Story

20x

Cutting speed increased

95%

Metal slags decreased

70%

Labor costs cut

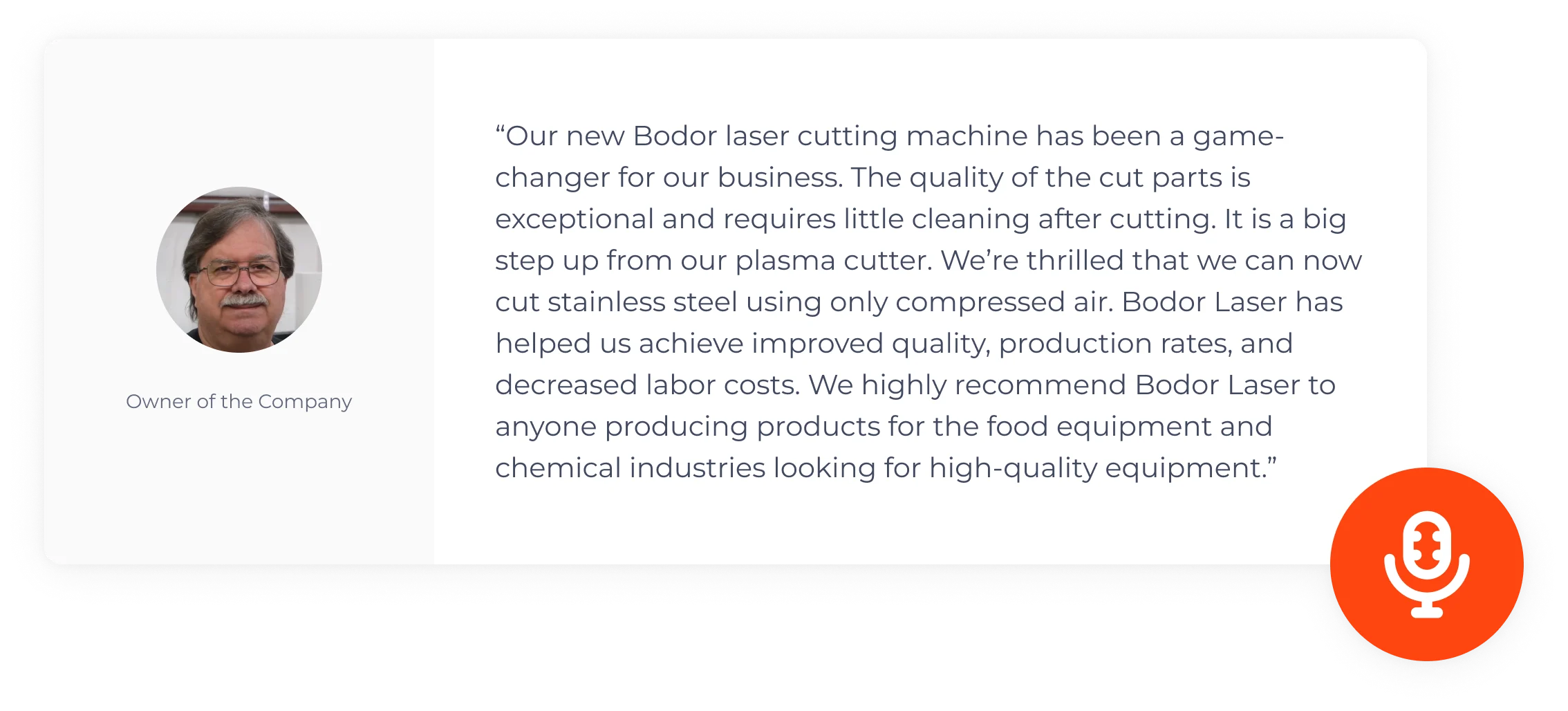

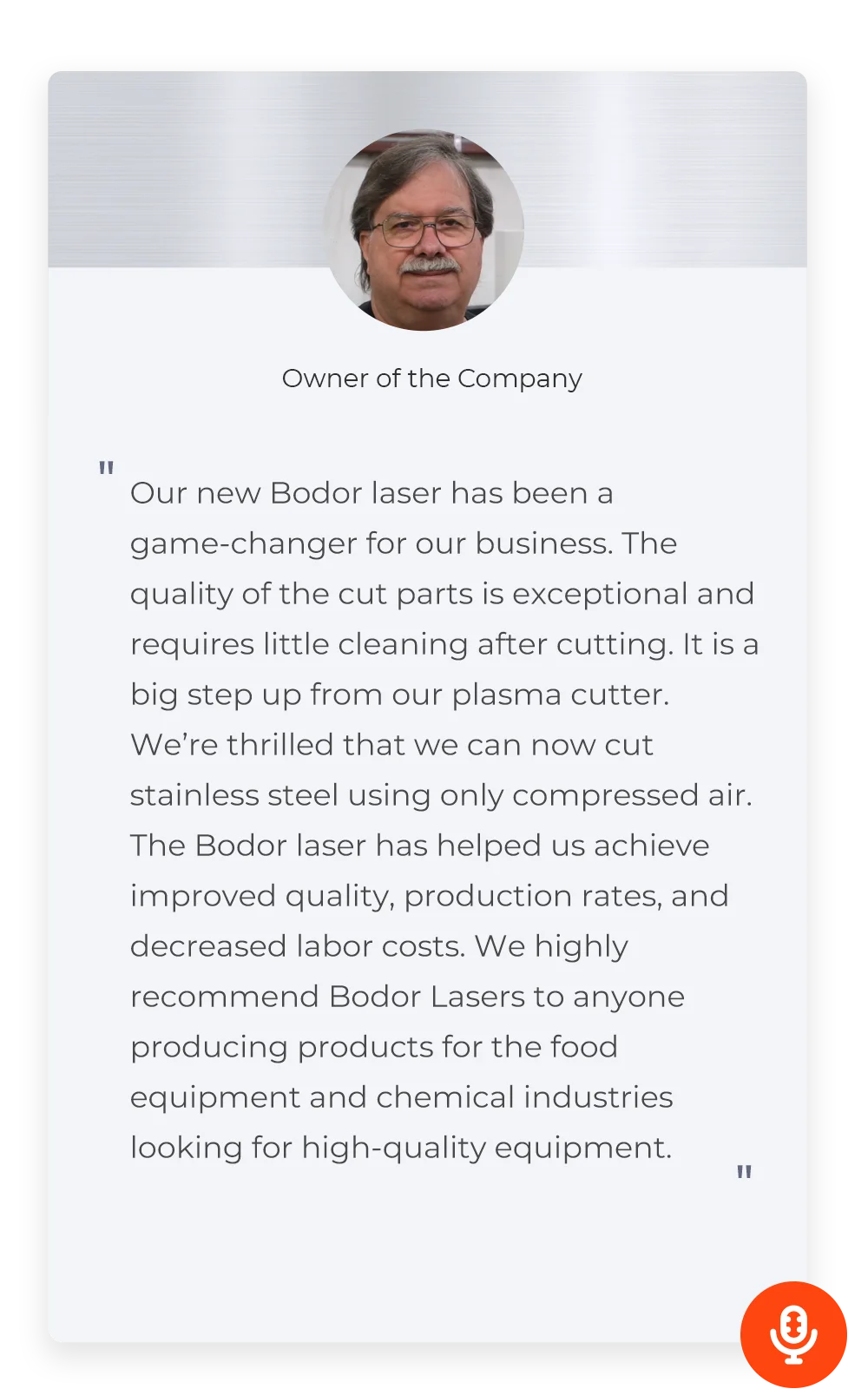

The company is a well-known sheet metal fabrication contractor for the food equipment and chemical industries located in Virginia, the United States. Its main business is processing 1-6mm stainless steel sheets. The company has built corporate relationships with a variety of brands and has a booming business.

INDUSTRY

Sheet Metal Fabrication

INSTALLATION TIME

Dec. 2022

LOCATION

Virginia, USA

The Plasma Cutting Machine Cut Inefficiently and Created Metal Slags

When processing 1-6mm stainless steel sheets using an outdated plasma cutter, the company went through quite a few challenges that were hard to conquer.

First came the low-efficiency problem that led to increasing delivery time. The plasma cutting machine worked at a considerably slow speed of 2.5m/min, limiting the production volume. In addition, the operators had to shut down the machine every 2 hours to change its nozzles and other consumables, which decreased the active working hours and production volume as well.

Another challenge was that stainless steel sheets processed by the plasma cutter had lots of adhering metal slags affecting product quality. To produce high-quality products such as coffee makers for the food equipment industry, the company had to hire more workers to grind the processed metals and remove the slags. As a result, this slagging problem brought up labor costs drastically.

Bring in Bodor A3 Laser Scanning Cutting Machine to Cut Faster and Better

To reverse the inadequate performance, the company needed to transform to a more advanced and efficient cutting approach to increase productivity and quality. The fabricator noticed the Bodor brand and the laser scanning cutting technology when researching laser cutting machines.

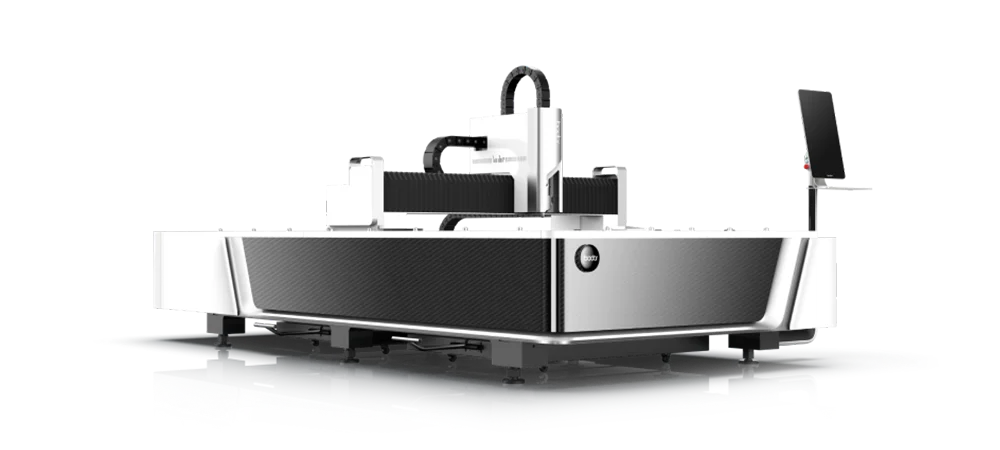

The professional and fast-responsive sales manager from Bodor contacted the company, understood its processing materials and needs, and recommended the A series with scanning cutting technology. This state-of-the-art technology is developed independently by Bodor based on the the integration of BodorPower laser source, BodorGenius Laser head, and BodorThinker control system. By reprogramming the cutting path algorithm, laser scanning cutting can achieve much faster speed, much thicker material thickness, and free of beam reflection compared with conventional lasers.

The metal sheet manufacturer was pretty satisfied with Bodor’s sales manager as he put himself into its shoes, truly considering what was the best cutting solution for this company, instead of just selling laser cutting machines. So, the company took his advice without hesitation and purchased a Bodor A3-3kW laser cutting machine.

Scanning Cutting Technology with A3 Laser Solution Surges Speed by 20-fold and Reduces Labor Costs by 70%

By transferring to the Bodor A3-3kw laser scanning cutting machine, the company reaps a lot of benefits. It now can cut 1mm stainless steel at an excellent speed of 50m/min, surpassing the plasma cutter by 20-fold and significantly boosting the production efficiency.

The company is fairly content with superior product quality as well. Stainless steel sheets cut by the A3 scanning model are smooth and non-slagging. Those products exhibit clean edges, smaller kerfs and heat-affect zones. The operators do not need to second-grind the processed products anymore, and it drastically reduces labor costs by 70%.

Seeing such great improvements, the U.S. metal fabricator is considering investing in a Bodor laser tube cutting machine to increase product lines and expand its business to a more diverse customer base.