How to choose the best speed for laser equipment to cut out high-quality materials

The power of the laser will affect the cutting speed of the laser equipment, and the cutting speed of the laser equipment will affect the cutting quality of the plates. Under the condition of a certain laser power, there is an optimal cutting speed range. If the speed is too fast or too slow, it will affect the flatness of the cutting material.

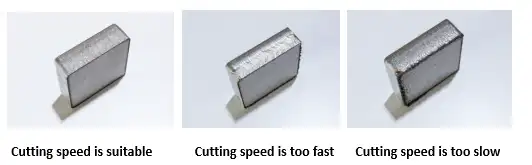

Cutting speed is too fast

1. The laser beam and the material are in contact with each other for a short time, which may result in the inability to cut and sparks.

2. Some areas can be cut, but some areas cannot.

3. The whole cutting section surface will be delaminated.

4. As a result, the plates cannot be cut off in time, the cutting section surface shows a diagonal grain, and the lower part of the plates will generate molten slag.

Cutting speed is too slow

1. The time of interaction between the material and the laser increases, resulting in over-melting of the cutting plate, and the cutting section surface is rough.

2. The slit will widen accordingly, causing over-burning in the smaller rounded or sharp corners, and the ideal cutting effect cannot be obtained.

3. The cutting efficiency is low, which affects the production capacity.

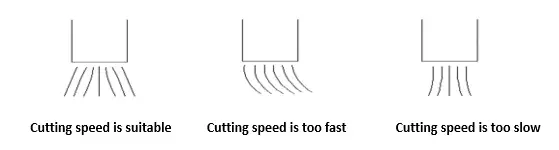

Judging method of cutting speed

1. The cutting speed is suitable: the cutting sparks spread from top to bottom, the cutting surface is stable, and there is no molten slag in the lower part;

2. The cutting speed is too fast: the cutting spark is inclined;

3. The cutting speed is too slow: the cutting sparks are not diffusive and few, condensing together.