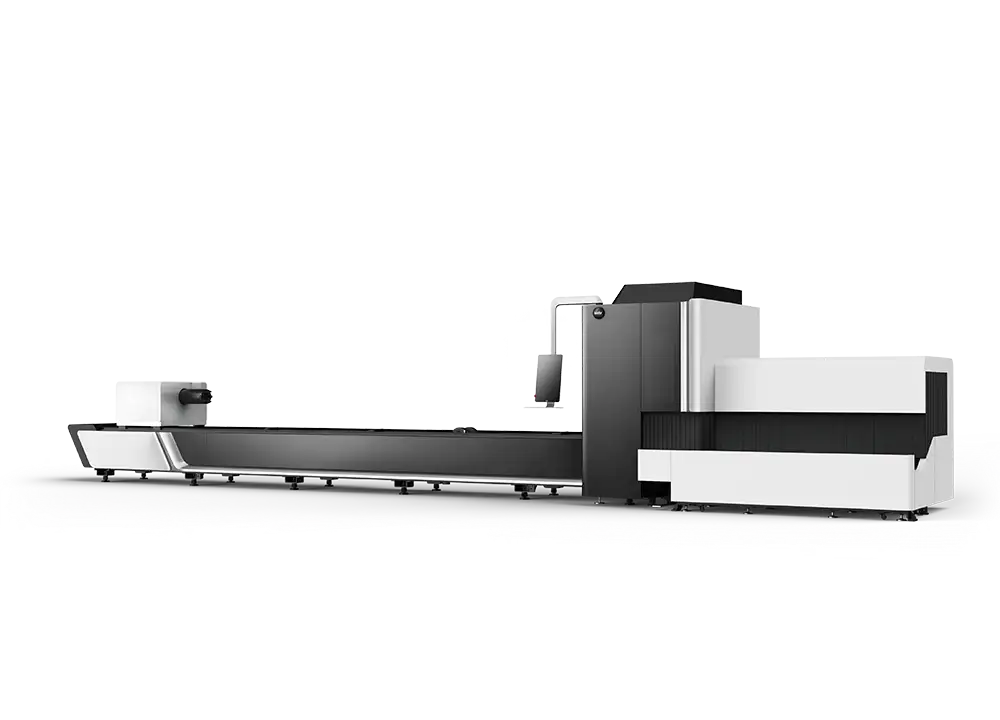

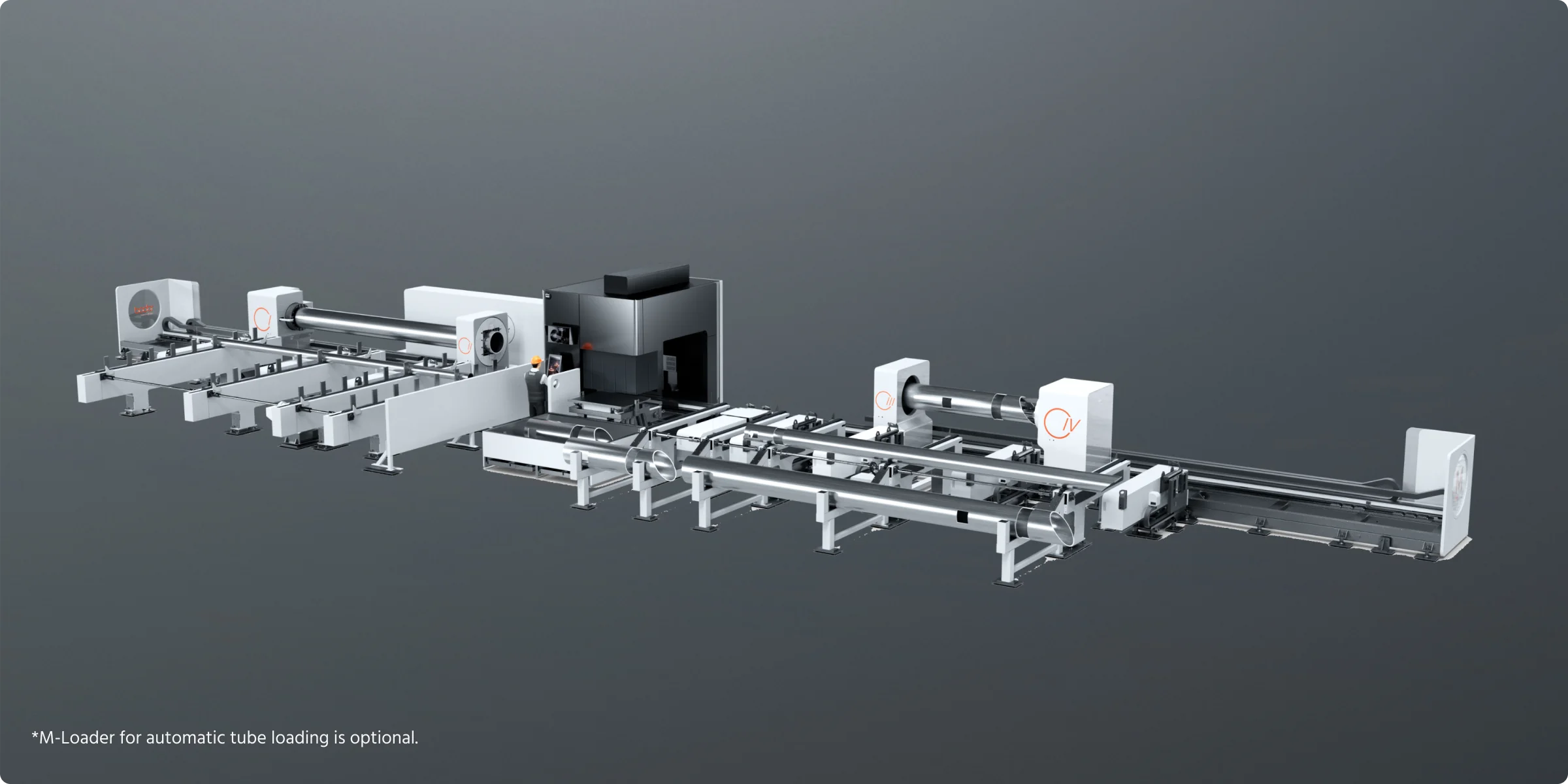

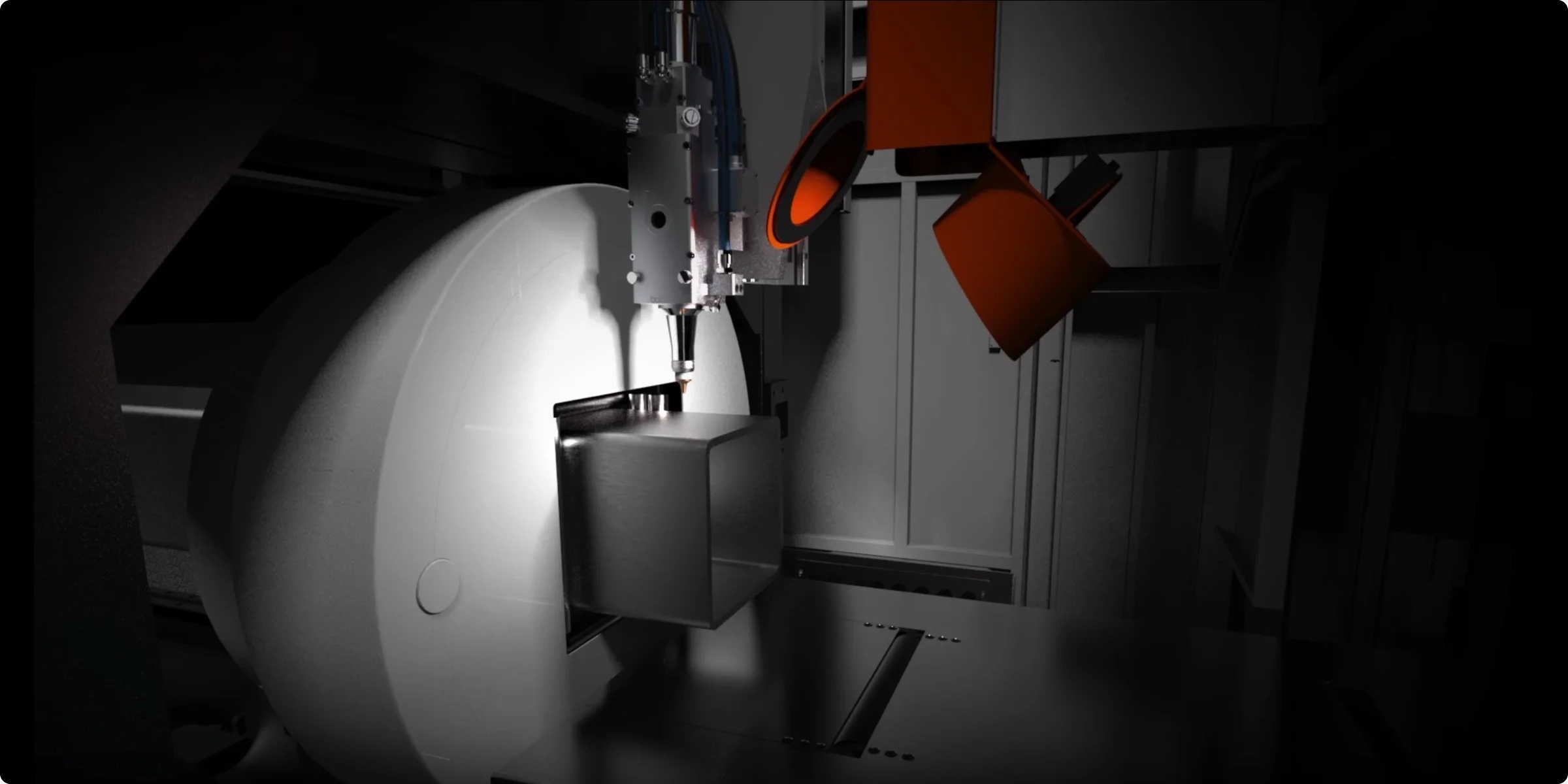

Bodor M5 Flagship Fiber Laser Metal Tube Cutting Machine

Discover a high-end laser cutting product along with its intelligent automation process. Equipped with 4 chucks, M5 aims to produce quality cuts with maximum productivity and zero excess materials.

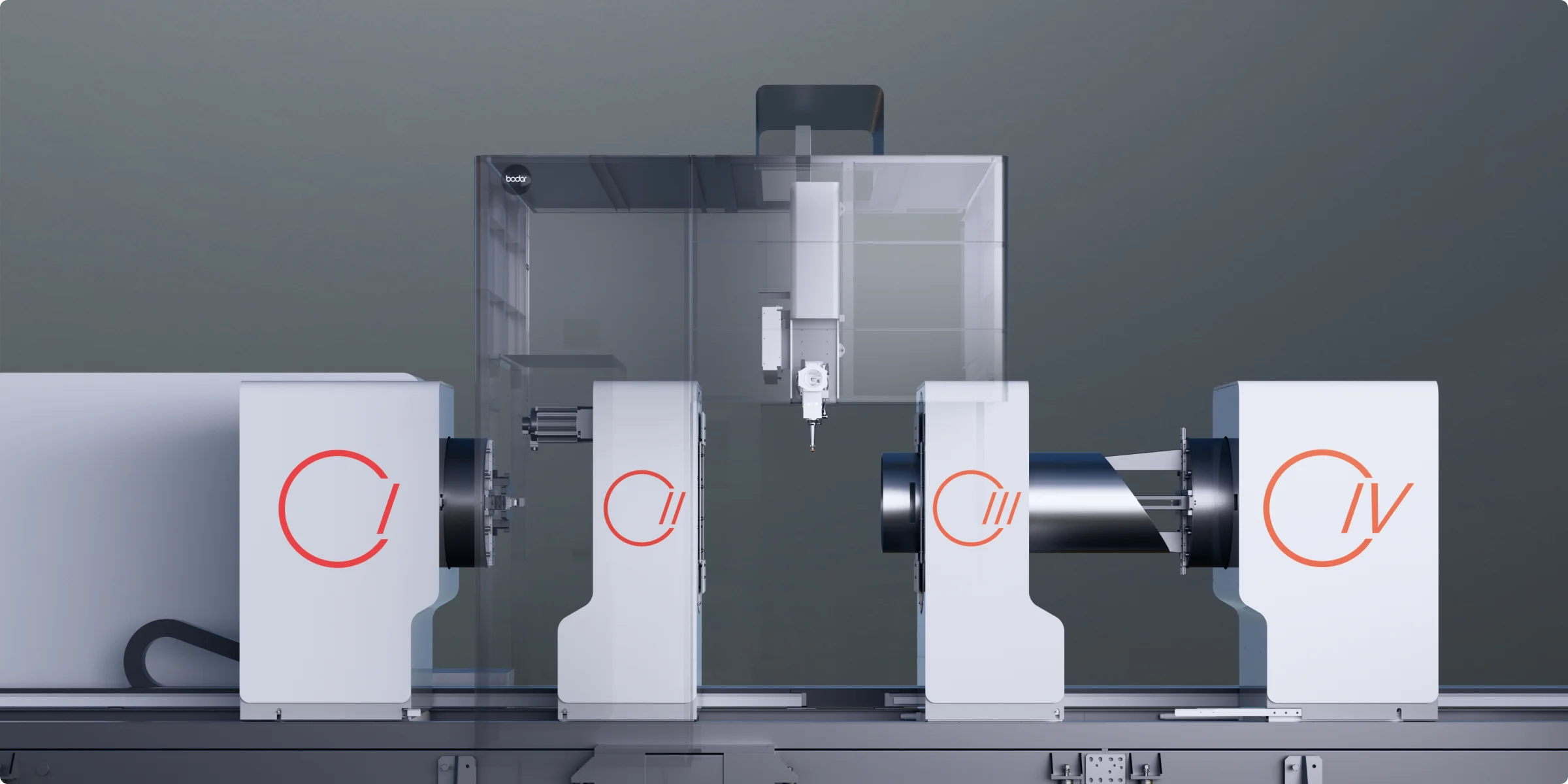

Enter the world of 4-chuck laser cutting

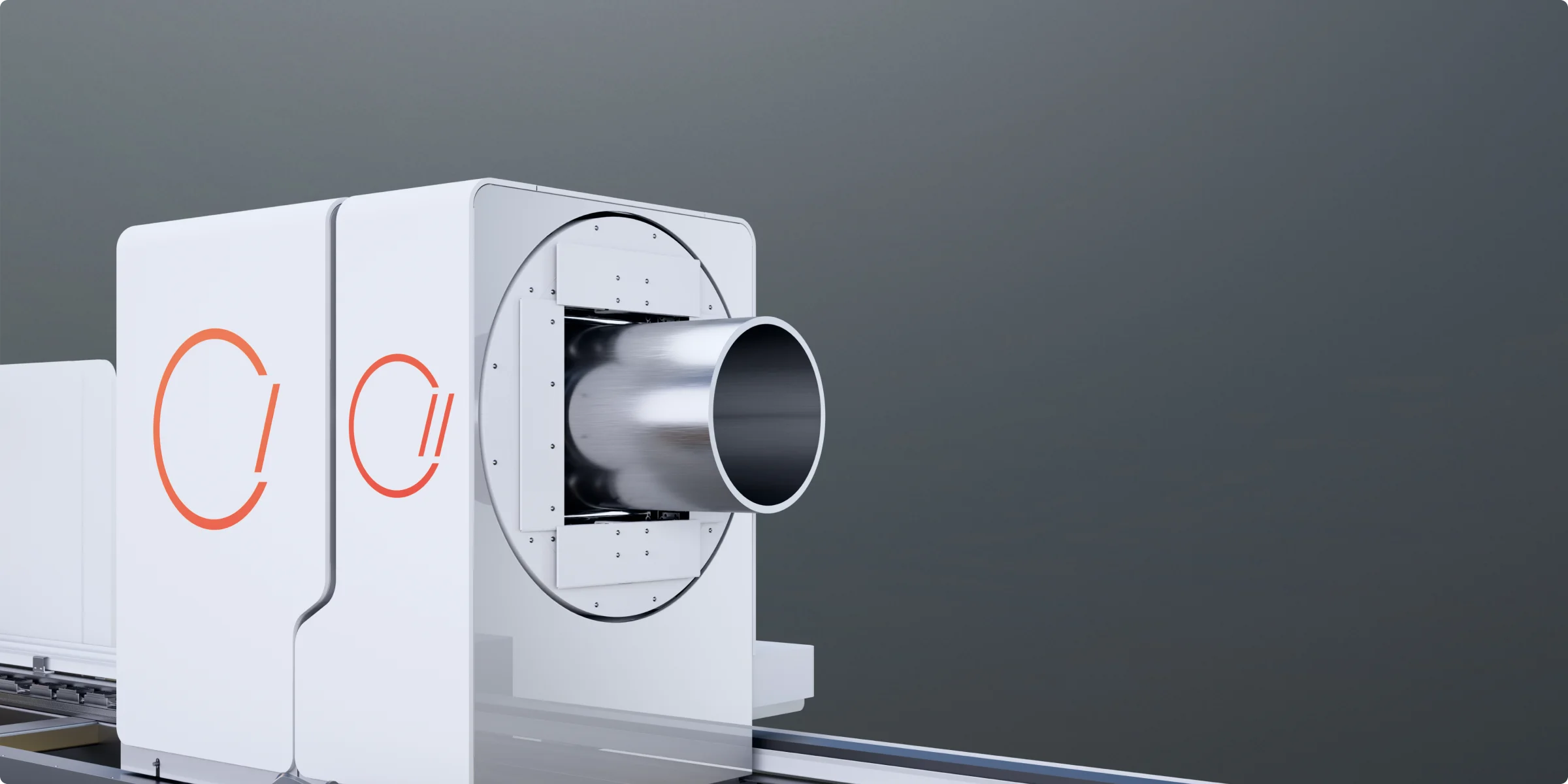

Excellent loading capacity

Fulfill diverse, hard-core cutting needs. Ideal for heavy metal tube processing, M5 gives you the ability to cut tubes with diameters up to 530 mm.

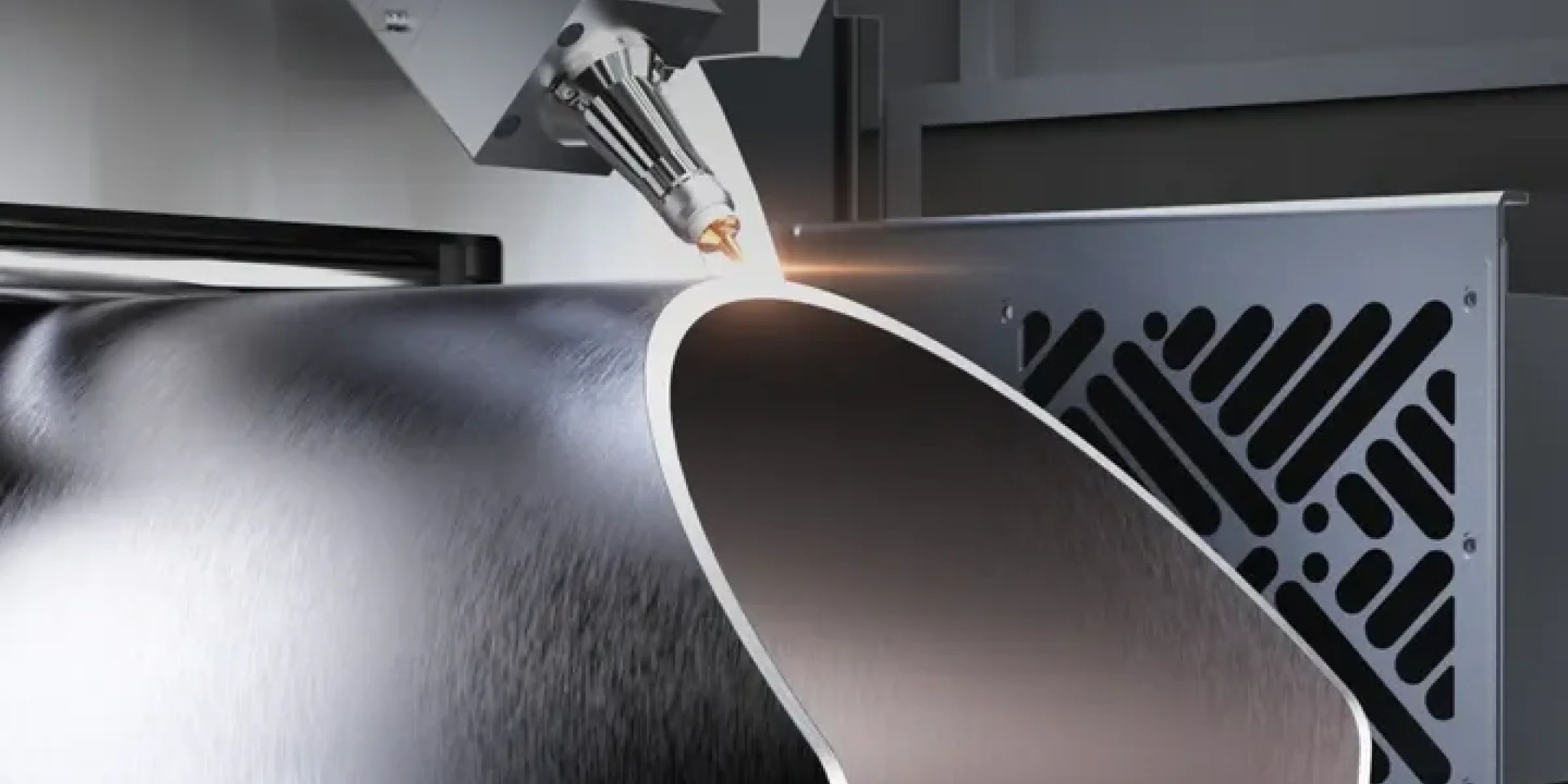

0 excess material processing

Minimize manufacturing waste from the source. During operations, M5 will help you utilize every piece of material to the largest extent possible, reducing waste and improving cost-effectiveness.

Safety enhancement

Provide a secure operating environment. M5’s 4-chuck mechanism ensures high-quality cutting without manual intervention, ensuring a hands-free operating environment with lower human costs.

Features & enhancements

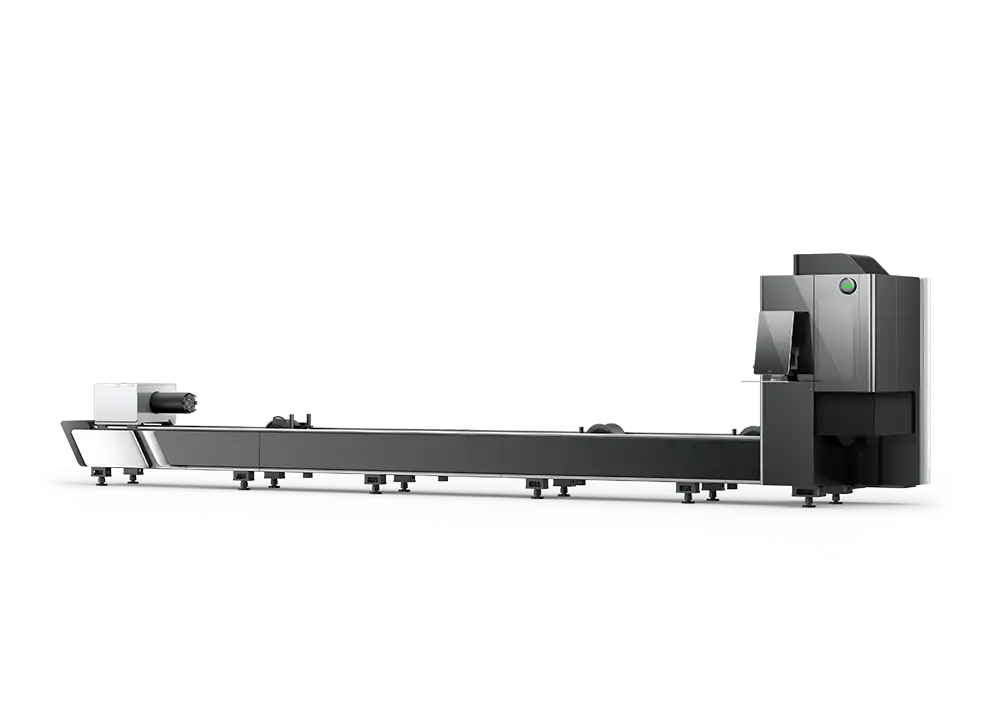

New floor-standing structure

M5 operates with extreme steadiness. Unlike wall-mounted designs, the acting force of the floor-standing structure is perpendicular to the ground, thus providing stronger support to the system as well as easy access for everyday work. Thanks to its open concept, the installation of M5 is quick and safe, significantly cutting down labor costs and turnaround time.

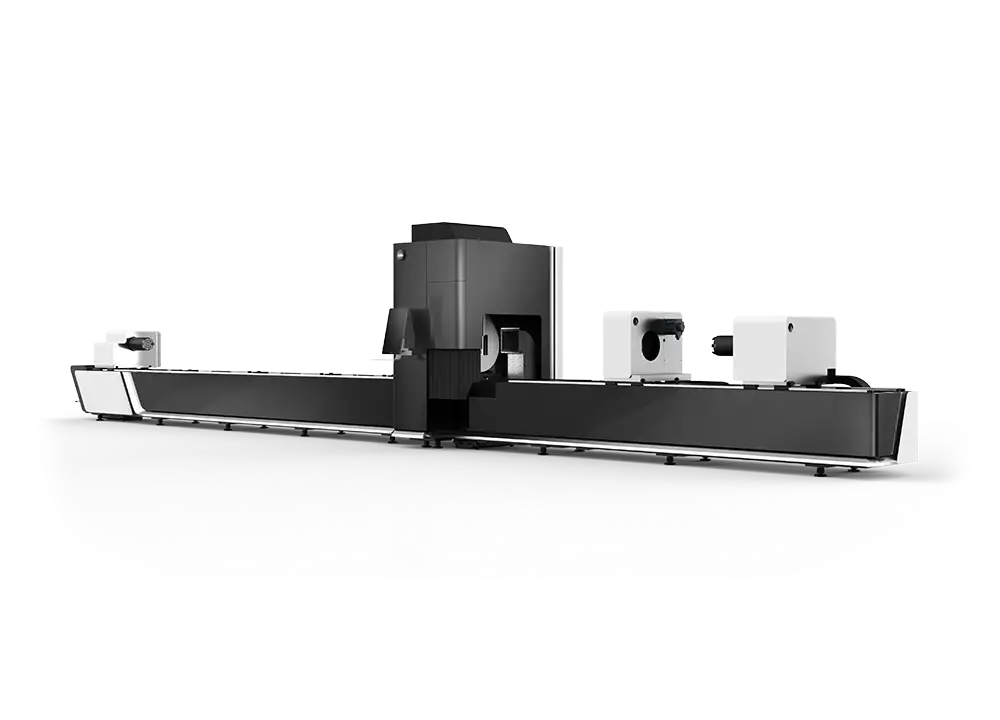

Airtight pneumatic chuck & intelligent cutting mode

Bodor’s airtight pneumatic chuck is intended to balance the act of high efficiency and low maintenance requirements. The 4-chuck mechanism of M5 completes cutting in just 2 secs. Its airtight feature makes the chuck dust-resistant, meaning that dust cannot contaminate or cause any negative effects on regular chuck operations.

The 4 chucks also enable M5 to cut effectively in two ways - for heavy tubes and for long-sized tubes. In heavy-cutting mode, you will be able to cut tubes with weight up to 2,500 kg. In efficiency-cutting mode, you will be able to cut tubes with length up to 12,000 mm. Through accelerating different cutting processes, M5 is particularly beneficial to multi-tasking users with heavy workload.

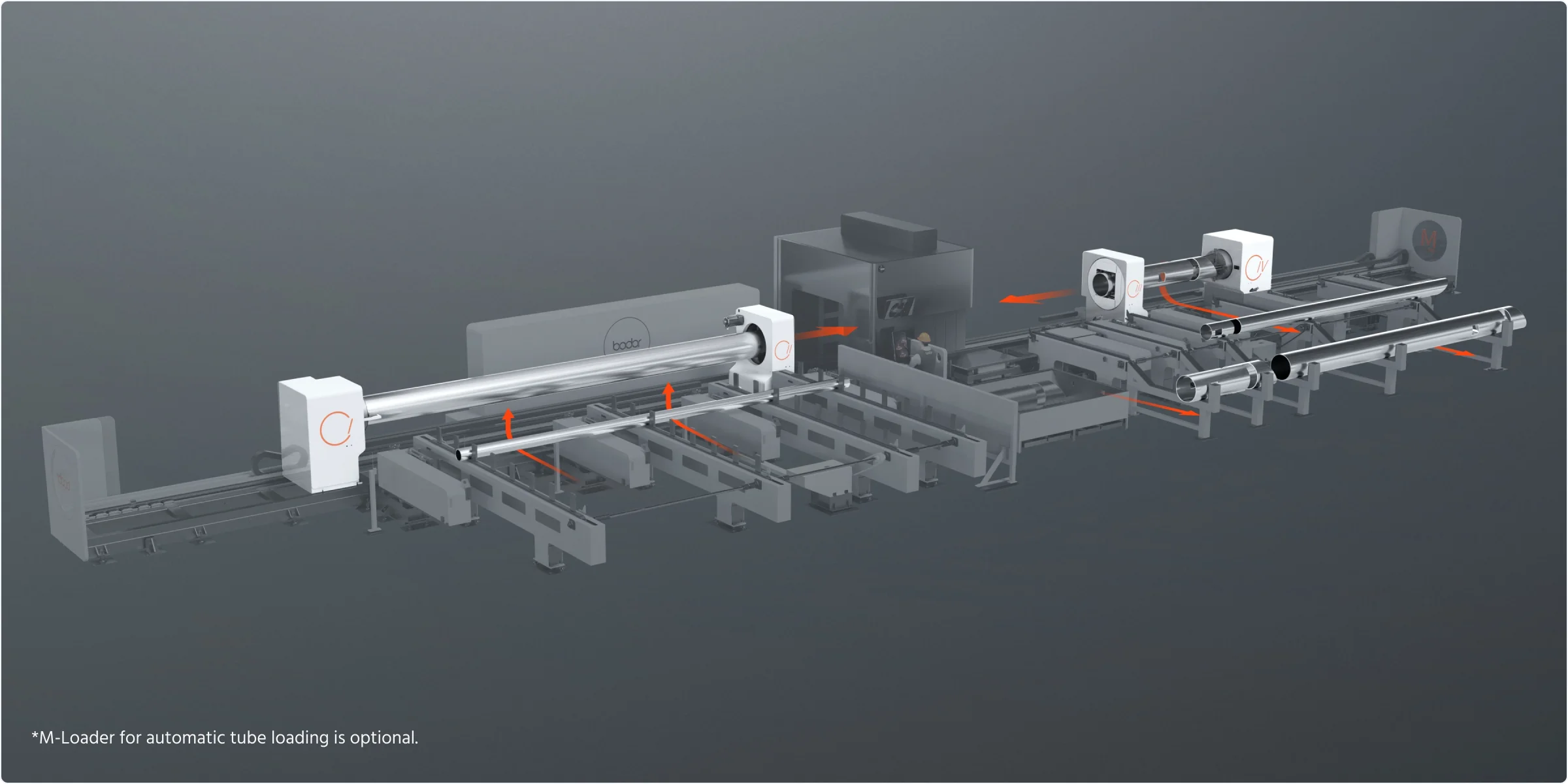

Fully automatic setup

M5 facilitates users to accomplish automatic loading and unloading processes for round, square, and rectangular tubes. Without any manual intervention, there is no downtime or risks of human errors. This guarantees that you have full flexibility to handle both large and small batches of projects.

Tackling manufacturing waste

Bodor strives to be as efficient as possible at converting raw materials into products and reducing the amount of waste generated. This is the reason why M5 is set to be waste-free in cutting operations. The extra 4th chuck of M5 enables clamping at full, making sure that M5 generates quality cuts even for the very last work piece. Without leaving leftovers, M5 is able to effortlessly process a wide range of raw materials and profiles.

Synchronous process integration

M5 offers maximum ease of operation thanks to its 4 chucks. The parallel block allows loading, processing, and unloading to run synchronously. With one piece of tube unloading, M5 loads a new piece and initiates cutting right away. “Time-consuming” or “long downtime” no longer exists in terms of M5.

Excellent bevel cuts

The bevel cutting function enables the production of high-precision bevel cuts in multiple degrees, optimizing subsequent assembly procedures and welding performance while lowering production costs.

Weld seam identification (optional)

With a simple camera set-up, M5 can quickly detect weld seams on a variety shapes of tubes, even those located on the inside. This option is particularly applicable to manufacturers who would like to avoid weld seams during laser cutting.

Specifications & parameters

| Laser output power | 12000W / 6000W |

| Chuck quantity | 4 |

| Shortest remaining material | 0 |

| Effective square tube cutting scope | □60*60-□530*530mm |

| Rectangular tube edge length | 80mm-510mm |

| Effective round tube cutting diameter | Φ80-Φ510mm |

| Max. machinable tube length | 12000mm |

| Max. chuck rotating speed | 40r/min |

| X/Y-axis positioning accuracy | ±0.05mm/m |

| X/Y-axis repositioning accuracy | ±0.03mm |

| Max. tube weight | 2500kg |

Applicable industries

M5 has met the manufacturing needs of large products and complex processes in heavy industries.

Pipelines for oil and gas

M5 demonstrates extraordinary strengths in cutting results when it comes to piping materials up to 20mm, making it the best choice for pipeline production in the Oil and Gas industry.

Aerospace

M5 is able to provide tailored solutions for the aerospace industry. It is especially applicable to the manufacturing of aircraft and spacecraft products.

Industrial architecture

M5 enhances the makes of industrial architecture like factories and power plants for a lower unit cost with more energy-efficient operations.

Elevators

One of M5’s core business scopes revolves around the supply and building of elevators as it brings in significant cost reduction.

Heavy machinery

Thanks to its large load carrying capacity, M5 exhibits an exceptional advantage in the production of heavy equipment like crawler tractors, skidders, excavators, and aerial lifts.