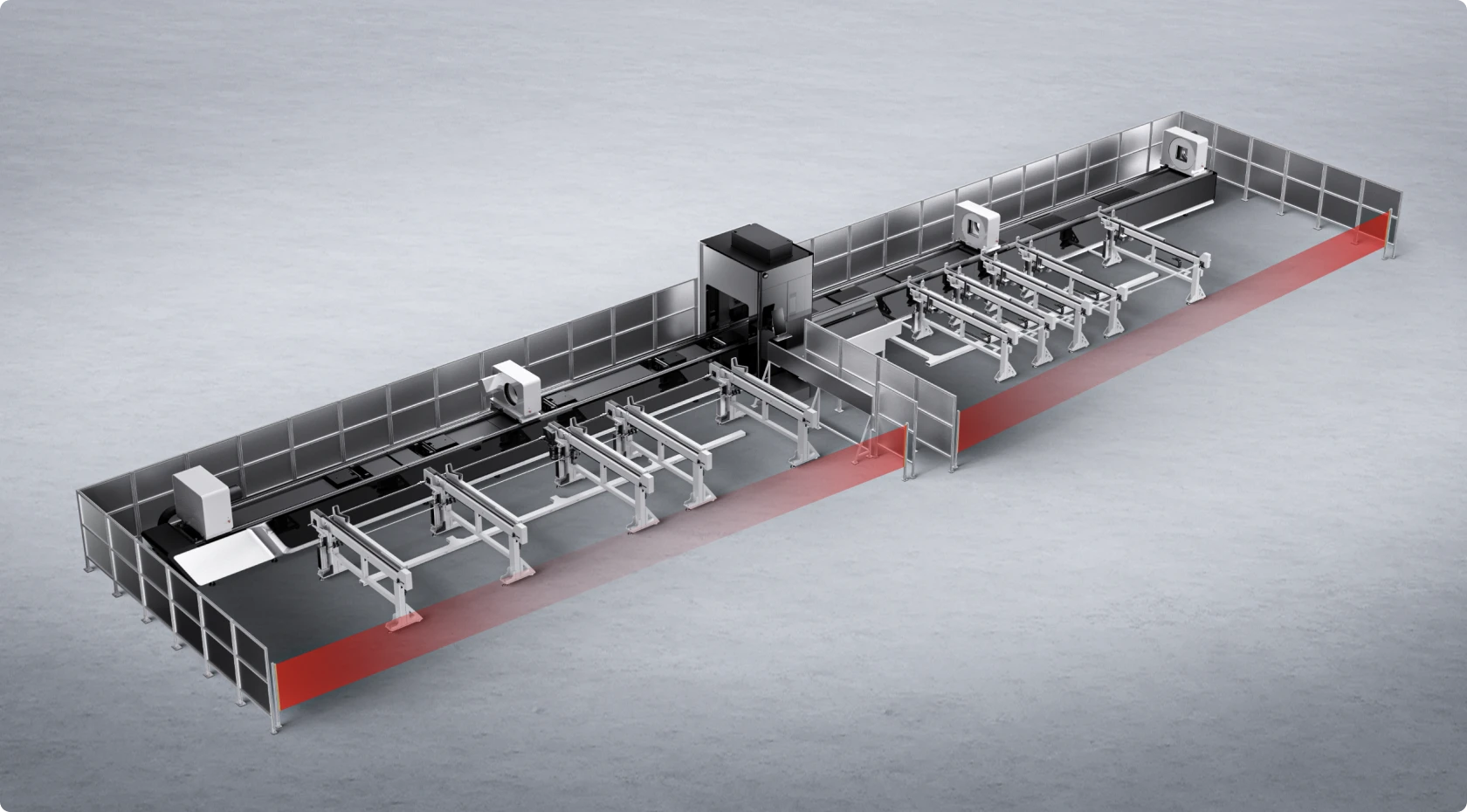

M-Loader

The M-Loader is an auxiliary device for the M2, M3, and M5 models, enabling automatic

loading of

round and square tubes, rectangular tubes, channel steel, and I-beams.