Dream or Droop; New Dream Series, Passion for High-quality Cutting

In early 2021, Bodor released a new slogan: Dare to dream , which means to encourage those who dare to dream and persevere in pursuing dreams. Since ancient times, the "dream" has always pushed mankind into a better future.

Do you pursue happiness or strive for a better life through hard work? Everyone does or did dream like that because it powers the hopes and aspirations. For Bodor, the dream means better laser cutting solutions for customers.

Thanks to the above-mentioned "dream" precisely, Bodor has been working with its customers to overcome obstacles and making great achievements. In the future, Bodor will strive for the best and lead the global laser cutting industry with the guide of Bodor’s "2025 Strategic Plan". Now in 2021, which we recognize as a vital year, Bodor intends to set a broader course for its dream by introducing new products and technologies.

The New Dream Series , a maglev laser cutting machine, which provides the optimal solution for high-quality laser cutting, attaches importance to meeting the needs of a better experience for its users, moreover, it represents Bodor’s passion for high-quality laser cutting.

Dream, A Maglev Laser Cutting Machine - Excellent Stability and Extreme Precision

Since the first laser was built by Theodore H. Maiman in 1960, we have entered into a new industrial revolution. It is likely to see that we will see laser-based technology continue to develop over the coming years.

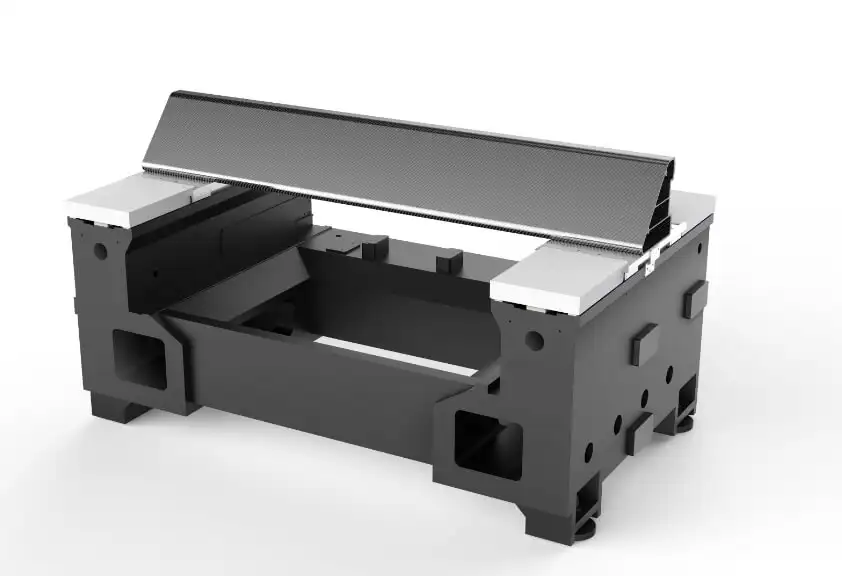

Bodor, a global laser cutting solution provider, pioneers the metal laser cutting technology, starting with an idea - expanding its customers’ business value of laser cutting to a higher level. The Bodor Dream Series, which aims at high performance, makes use of a maglev linear motor and cast marble bed, leading ahead in the field of stable and precise metal sheet cutting.

· Maglev linear motor

Thanks to the "Magnetic levitation theory", basic of the motor drive technology, the linear motor brings no mechanical friction, higher precision, more stable movement, simpler maintenance, faster response, shorter processing time, and higher efficiency.

· Marble machine bed

Using cast marble, the original resistance to thermal radiation and its heavy body of excellent stability perform incomparable vibration absorption, vibration resistance, and a longer life cycle with no deformation.

Dream, Carbon Fiber Crossbeam - Rapid Response and Efficient Processing

For enterprises, when production efficiency improved, the cost reduces and the pressure of price competition can be withstood as a result, which enables the company to own more market shares. Therefore, profits increases in correspondence to the improvement of production efficiency if the price does not change. In the metal cutting industry, once a company has a strong capability of cutting wide ranges of metal under high speed and efficiency, the competitiveness of it will be effectively enhanced. Therefore, an ideal choice for laser cutting of high speed and high precision motion to increase efficiency is definitely needed to validate the efficiency and profit theory. With the selected carbon fiber, which impresses with lightweight for less load, the crossbeam of Dream Series is just the best start.

· Carbon Fiber Crossbeam

The carbon fiber crossbeam, a kind of non-metallic material, has no material stress and no stress deformation. The cross-section of the crossbeam made of carbon fiber by vacuum hot pressing adopts the typical mechanical stable structure of triangular prism, with ultra low-density, lighter weight, and stronger rigidity, so that the dynamic performance is perfect.

Last but not least, the series, which is also configured with many intelligent functions such as "edge-seeking by light eyes", "active anti-collision by laser head" and "fully automated process by one-click", speaks for Bodor’s ambitiousness for excellent perfect and endless progress. At the same time, Bodor aims to make the dream greater and the passion more intense by working more closely with its customers.

Bodor Laser is a professional manufacturer and exporter dedicated to the design, R&D, and production of fiber laser machines that are widely used for cutting different metal materials. All of our products comply with international quality standards (CE, SGS, ISO9001, etc.) and are greatly appreciated by customers around the world. With 20 service languages, knowledgeable sales and after-sales team, 24/7 service, a worldwide market network covering more than 150 countries, we reach out to customers all over the world and look forward to all potential partnerships. Keeping in mind responsibilities for the well being of its staff and the society, Bodor is determined to gain world recognition with intelligently Made-in-China and change human life with laser technology.