Laser Cutting Tackling Problems Caused by Plasma Cutters

Molloy Invests in Bodor P4 Sheet Laser and T2 Tube Laser Machines to Cut Steel with Low Costs and High Precision

Molloy’s Success Story

70%

Costs saved

50%

Cutting precision enhanced

60%

Product quality improved

Molloy Engineering, established in 1983, initially specialized in crafting gates and railings. Over time, it has grown its operations and attracted local builders. Molloy fabricates various metal products, from small brackets to large conveyor machines. Molloy's excellence has been recognized on various platforms, being the runner-up in the Yell Best Family Business Awards.

INDUSTRY

Metal Fabrication

INSTALLATION TIME

July 2022

LOCATION

Lurgan, Northern Ireland, UK

Inadequate precision and high costs problems of plasma cutting demand prompt solution

Molloy Engineering is an outstanding expert in metalworking, boasting over 40 years of experience. However, it encountered significant challenges while utilizing plasma cutting machines. The inherent limitations of the technology posed obstacles to the company's operations.

One primary issue is that plasma cutting struggles to achieve the level of precision required for intricate metal fabrication tasks. When cutting steel, the wider kerf width and thermal distortion often resulted in inaccuracies, especially with complex workpieces. Moreover, the frequent maintenance requirements of plasma cutters significantly elevated costs for Molloy. The necessity for regular replacement of consumables such as electrodes, nozzles, and shields incurred ongoing maintenance expenses.

Compromised quality due to precision issues led to rework and potential customer dissatisfaction, while elevated production costs hindered the company's competitiveness. These challenges highlighted the importance of seeking alternative solutions to ensure the company's continued success in metal fabrication.

Making a strategic decision to adopt laser cutting technology from Bodor

To address the problems of precision and costs, Molloy decided to invest in new cutting technology. The company explored various options through a local agent. Among the available choices, Bodor fiber laser cutting machines stood out as the most ideal solution.

Before purchasing, Molloy took steps to evaluate the Bodor machines thoroughly. They arranged for on-site demonstrations and inspections to firsthand assess the machines' capabilities. Impressed by Bodor machines' advanced features, precision, and efficiency, Molloy recognized the potential for significant improvements in their metal fabrication processes.

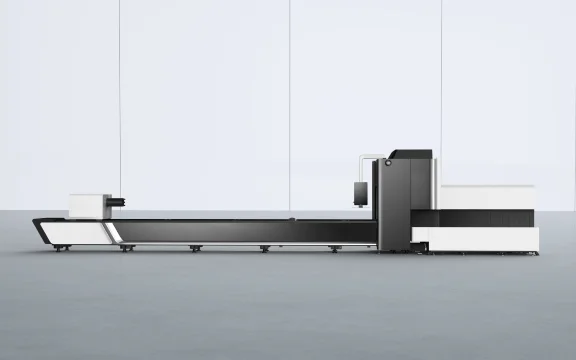

As a result, Molloy invested in a Bodor P4 12kW high-powered sheet metal laser cutting machine. The P4 machine enables Molloy to achieve superior results in processing carbon and stainless steel sheets, meeting the stringent quality demand of its customers. Encouraged by the positive outcomes, they acquired another Bodor machine of T2 6.5kW model to cut metal tubes, further expanding its productivity.

Cutting precision elevated by 50% while cost saved by 70%

The introduction of Bodor P4 and T2 laser cutting machines has brought about significant positive effects. Not only have costs been reduced by an impressive 70%, but the precision of cutting has also seen a remarkable surge of 50%.

Molloy can now achieve intricate designs with greater accuracy and consistency. Thanks to BodorGenius, Bodor's advanced self-developed laser head, the machines can cut various materials efficiently and effortlessly.

Furthermore, Molloy has experienced substantial savings attributed to decreased material waste, minimized labor requirements, and lower maintenance charges. Bodor machines are equipped with innovative functions, such as intelligent remnant layout and one-click processing, that can elevate the material utilization and automation level.

Implementing Bodor P4 and T2 laser cutting machines has proven to be highly beneficial. The substantial cost savings and increased cutting precision have revolutionized manufacturing processes, allowing Molloy to thrive in the competitive market.