FabTech Boosts Productivity with Bodor T Series Tube Laser

FabTech Sheet Metal, an UK metal fabrication solution provider, has successfully expanded its tube processing capabilities with the addition of Bodor’s classic tube laser T3

FabTech’s Success Story

50%

Costs saved

40%

Cutting efficiency increased

50%

Product quality improved

As an expert in laser cutting and multi metal fabrication, FabTech Sheet Metal manufactures a diverse range of products for all types of industries across the UK. With extensive experience, FabTech brings design ideas to life and create based on business requirements

INDUSTRY

Metal fabrication

INSTALLATION TIME

08/2023

LOCATION

Peterborough, UK

FabTech Sheet Metal provides customized metal fabrication solutions for many organizations in the UK. Specializing in precision sheet metalwork, the company offers comprehensive services from design and prototyping to production and finishing. With a focus on sheet metal processing, FabTech was interested in broadening their production capacities to include tube metal.

The challenge

As the initial and crucial step in metal fabrication, laser cutting demands a machine with excellent performance and strong ROI. To achieve customized metal designs, the machine also needed to be versatile and flexible.

For FabTech, this meant finding a solution that could handle metal tubes while meeting their high standards and goals - something that many traditional CNC tube cutting machines were unable to do.

Recognizing the limitations of conventional methods, FabTech began exploring alternatives to meet their production demands more efficiently. Their exploration led them to discover that, when operating at the same power, fiber laser cutting machines offer cutting speeds that are 2 - 3 times faster than CO2 laser cutter. In the meanwhile, fiber lasers yield narrower kerfs as well as superior processing quality due to their higher energy density and smaller spot sizes.

How Bodor helps

FabTech reduces costs and improves quality through the T3 3kW Professional Model

As a result, the company was determined to invest in the latest fiber laser technologies to obtain first-class tube processing results.

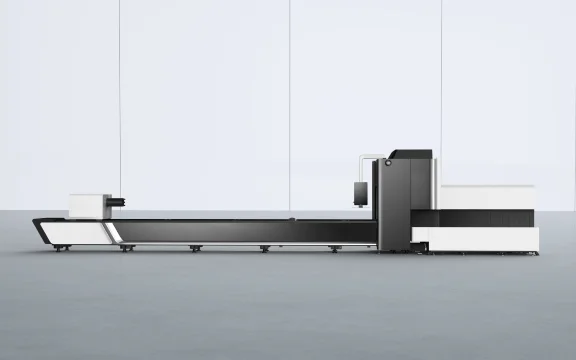

In August 2023, FabTech initiated a partnership with Bodor. From Bodor’s range of tube cutting systems, FabTech selected the T3 3kW tube laser, a classic Professional Model. The Bodor T series is known for its exceptional cutting speed (up to 160m/min) and intelligent features, ensuring precision in tube fabrication projects while offering user-friendly and intuitive operations.

Additionally, T series allows users to manufacture standard and customized-shaped steel tubes for their application needs, thanks to the capability to process tubes in square, rectangular, flat sided oval, elliptical and many other custom shapes in a variety of metals.

Bodor’s T3 3kW tube laser proved to be the ideal solution for FabTech as it effectively addressed the production issue they were facing.

As a dedicated partner in optimizing production lines, Bodor recognizes the importance of providing reliable after-sales and support services. Once the order was confirmed, Bodor’s customer service team quickly completed the installation process for FabTech.

The FabTech team was impressed by the performance of Bodor’s T3 tube laser, and will very likely invest in another Bodor machine in the near future.