Replacing plasma cutters with laser cutting machines

A Polish Company Expands Its Range of Cutting Materials Using Bodor P3 and K2 Machines

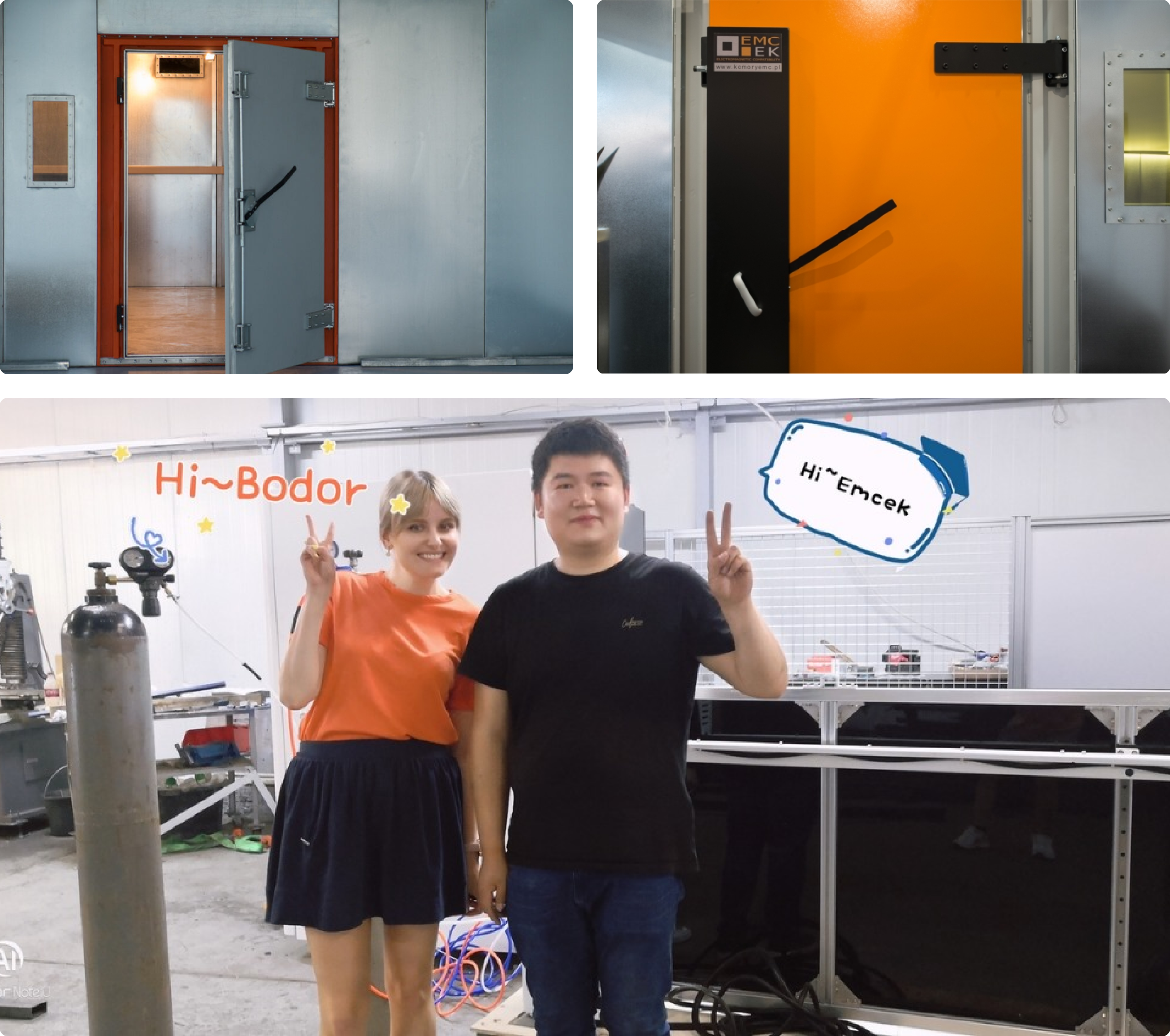

EMCEK's Success Story

Copper

Materials range widened

2x

Cutting efficiency increased

50%

Product quality improved

EMCEK is a leading Faraday cage manufacturer based in Poland, specializing in electromagnetic compatibility (EMC) solutions for over 15 years. It is distinguished in the industry for its collaborative partnerships across diverse sectors. It offers comprehensive services spanning design, production, installation, and maintenance. EMCEK maintains full autonomy in manufacturing, ensuring detail and quality at every production stage.

INDUSTRY

Special Equipment

INSTALLATION TIME

2019

LOCATION

Antoninów, Poland

Slow speed and bad quality of plasma cutting impeded the development of EMCEK

EMCEK, an experienced EMC solutions provider based in Poland, has rich experience manufacturing Faraday cages. However, their development was once hindered by their outdated processing equipment, particularly the plasma cutters.

Plasma cutting machines operate by melting materials using high-temperature plasma to achieve cutting. Unfortunately, this process can be time-consuming, leading to slow cutting speeds. Besides, the heat generated by the plasma swiftly dissipated through the material, which resulted in a poor cutting effect. This is especially true for materials like copper that have a high thermal conductivity, which makes them almost impossible to cut with plasma cutters.

As a result, these outdated machines failed to keep up with the increasing demand for precision and efficiency in manufacturing high-quality Faraday cages. The predicament was pushing EMCEK to a disadvantage in the intensely competitive market. The company realized it was time to change its processing methods.

Replacing plasma cutting with two Bodor fiber laser cutting machines

To produce Faraday cages with superior quality, EMCEK started seeking solutions to replace plasma cutting. After the consultation with a local dealer, they focused their attention on Bodor's fiber laser cutting machines.

Booking an appointment with Bodor, EMCEK's team got to see the advanced machines up close at the local factory. They were attracted to the excellent performance of Bodor's machines, which boasted lightning-fast processing speeds and top-notch cutting quality. One technology that particularly caught their attention was laser scanning cutting - Bodor's very own innovation designed for high-reflective materials. The experience left the team intrigued and excited to learn more about Bodor's cutting-edge technology.

MCEK was gratified to receive tailored solutions from Bodor's sales team, which led it to invest in a top-performing P3 sheet metal laser cutting machine. Its satisfaction with P3's steady performance over a year convinced it to order the K2 1kW laser cutting machine for better processing of tube materials.

Achieving 2x higher cutting efficiency, 1.5x better product quality, and copper cutting

As a result of this upgrade, EMCEK has not only maintained but solidified its position as a leading manufacturer of Faraday cages.

The implementation of Bodor laser cutting machines has brought about significant improvements across multiple fronts. The switch to laser cutting machines from plasma cutters has considerably improved EMCEK's processing speed, resulting in more efficient production processes and shorter turnaround times. The adoption of Bodor's self-innovative laser head, BodorGenius, has yielded consistently high-quality cutting results, ensuring precision and reliability in every manufactured piece.

Moreover, Bodor's laser scanning cutting technology has enabled EMCEK to expand its range of cutting materials, including the introduction of copper cutting capabilities. It can now better offer and cater to diverse customer needs.

These advancements have not only enhanced the overall competitiveness of EMCEK's products in the market but have also reinforced its reputation as a trusted provider of EMC solutions.