Transforming from Outdated CO2 Cutting to Unmatched Productivity

Dufusion’s Evolution to Revitalize Precision and Efficiency with Bodor P3 Fiber Laser Machine

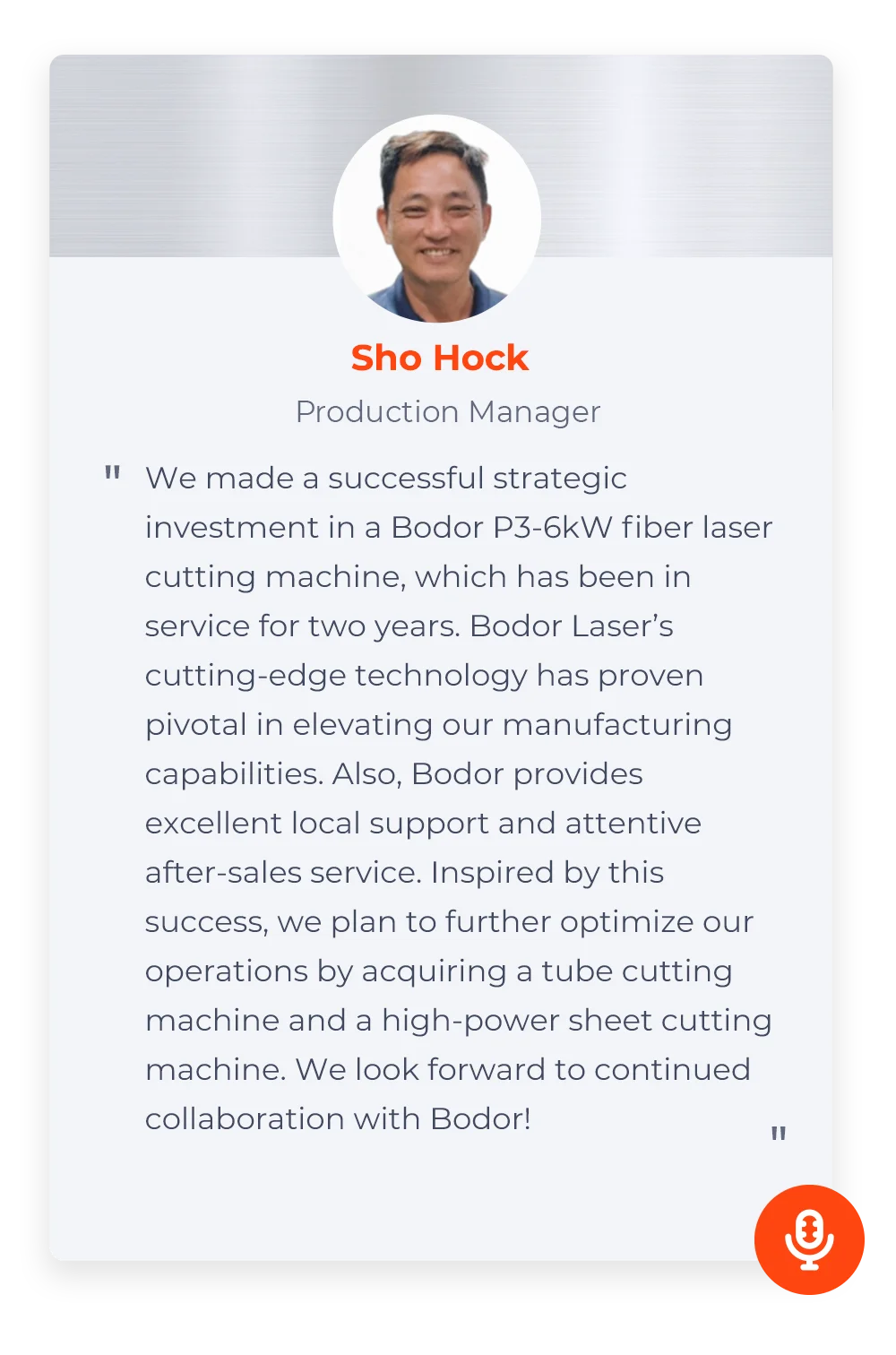

Dufusion’s Success Story

50%

Costs saved

30%

Cutting efficiency increased

60%

Product quality improved

Dufusion Sdn. Bhd, incorporated in 2011 in Penang, Malaysia, is a subsidiary of Dufu Technology Corp. Berhad, which has been listed on the main market of Bursa Malaysia in 2007. Their expertise spans various areas, including the manufacturing of precision steel molds, metal components, and medical instruments. As a world-leading entity in the fields of precision machining and engineering, Dufusion is committed to continuously exploring innovative methods to enhance processes and facilities.

INDUSTRY

Metal Fabrication & Medical

INSTALLATION TIME

August 2022

LOCATION

Penang, Malaysia

Dufusion's pursuit of precision and speed: moving beyond the constraints of outdated CO2 laser cutting

As a thriving enterprise, Dufusion faced a predicament with its CO2 laser cutter. This machine, once a capable companion in the manufacturing journey, revealed limitations in precision and processing speed.

The crux of the matter lay in the inherent characteristics of the CO2 laser. Its elongated wavelength and modest photoelectric conversion efficiency became stumbling blocks, impeding the finesse required for intricate manufacturing tasks. In addition, the restricted power output of the CO2 laser posed a bottleneck, placing constraints on its cutting speed. The repercussions were evident in compromised precision, hindrances in intricate tasks, and lengthy production lead time, collectively affecting the overall efficiency and competitiveness of Dufusion in the dynamic market.

To meet the dynamic demands of the market, Dufusion embarked on a quest for solutions. The decision to utilize new processing technologies, which would not only address these challenges but propel the company to a greater competitive edge in the ever-evolving manufacturing landscape, became imperative.

A strategic upgrade: enhancing quality and efficiency with fiber laser cutting technology

In the quest to enhance manufacturing efficiency, Dufusion embarked on a transformative journey where the realization dawned that fiber laser cutting was an ideal choice. The shorter wavelength from the fiber laser source allows for exceptional cutting speed and efficiency. As metals strongly absorb light waves, users can achieve intricate and high-quality cuts with outstanding precision and smooth edges in a short time.

Driven by this insight, Dufusion sought fiber laser cutting solutions and discovered Bodor fiber laser cutting machines. Introduced by Bodor sales representatives, Dufusion was captivated by the Bodor P series machines. The P series, dual-platform sheet laser cutting machines with parallel exchange structures, boasts high processing efficiency and cost-effectiveness, making it a formidable tool in the metal cutting domain. Bodor’s self-developed BodorPower laser source and BodorGenius laser head offer exceptional performance, perfectly addressing the challenges faced by Dufusion.

Later, in May 2022, Dufusion purchased a P3-6kW fiber laser cutting machine from Bodor, putting it into operation three months later.

Elevating productivity to new heights under the help of Bodor P3 fiber laser cutting machine

Since adopting the Bodor P3-6kW machine, Dufusion has experienced a substantial improvement in both production precision and speed. In addition to the outstanding performance of core components like BodorPower and BodorGenius, the P3 machine is equipped with various intelligent technologies. For instance, the one-second edge searching feature rapidly and accurately locates the vertices and offset angles of the sheet, facilitating efficient cutting.

The positive impact on Dufusion’s operations is profound. Enhanced precision translates into the ability to undertake more intricate manufacturing tasks, meeting the demands of diverse and complex projects. The accelerated cutting speed not only boosts overall production efficiency but also reduces lead times, enabling Dufusion to respond more promptly to market dynamics.

Through a strategic upgrade to fiber laser cutting technology, the company not only overcame its hurdles but also achieved remarkable innovation. In this journey of challenges met and conquered, Dufusion proves its status as a leader of success in the manufacturing landscape.