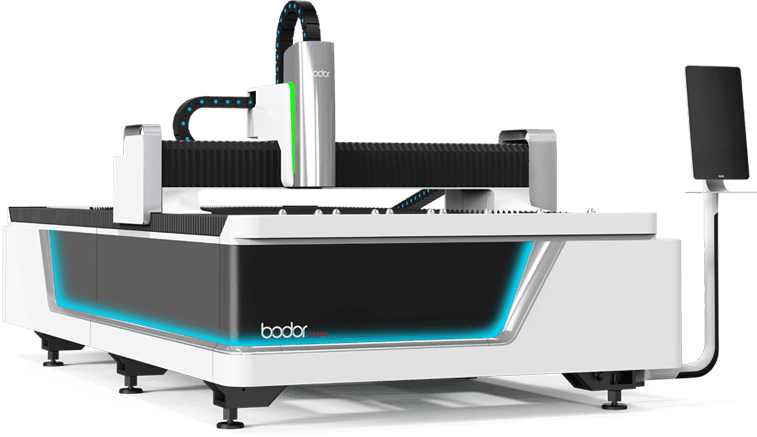

Amiral gemisi Ürün

El tipi lazer kaynak makinesi

CLOSE

Video

Mold pouring, clone production; integrally formed, reject splicing

Using flake graphite cast iron, the lowest tensile strength of which is 200MPa. High carboncontent,

high compressive strength and high hardness. Strong shock absorption and wearresistance. Low

thermal sensitivity and bed gap sensitivity reduce the loss of equipment in using, so the machine

accuracy could maintain for a long time, and no deformation in a life cycle.

Casting lathe bed Mechanical principle advantage

Machine bed focuses on processability, stability and damping capacity. Q235A is a low carbon steel, the damping capacity is low. While gray iron has high carbon content,and the main form of carbon is flake graphite, this structure could improve shock absorption and wear resistance and reduce wastage of machine bed during processing.

All-in-one-shaped casting process after aging treatment,we can ignore its heat induced internal stress,that is to say it has high stability and could maintain machine tool accuracy.

While casting lathe bed is integrated with single material, it can choose optimal force bearing point and supporting structure to make the whole mechanical property of lathe bed perfect.

Much more stable

Much more accuracy

Much more anti-shocking

Casting bed has a high request on the technical strength and supply chain’s quality, especially the casting structural design. It is difficult to make structural design fit with casting process. As the workpiece size is too large, if lacking casting experience, it is easy to cause casting defects, such as trachoma, loosing, broken and other defects. We have strong technical strength and supply chain to ensure that we can produce high-quality casting bed.