Bodor Tech Blog

Trending and helpful laser knowledge for your success

Why Laser Technology is Winning Over Top Metal Fabricators in the FAB40?

The metal fabrication industry has long been the backbone of manufacturing, and today, laser technology is at the forefront of reshaping this sector. In this blog post, we'll delve into the world of metal fabrication, explore the latest trends in 2024, and uncover why an increasing number of top metal fabricators are eagerly adopting laser technology.

What exactly is metal fabrication? and what's new in 2024?

Metal fabrication is a vital cog in the machinery of manufacturing. It spans a wide spectrum, from crafting minuscule components to erecting grand structures. Beyond traditional domains like construction and automotive manufacturing, metal fabrication now plays a pivotal role in emerging fields such as electric vehicle production and renewable energy. The industry's trends point to sustained growth, particularly in high-tech sectors.

Recent data indicates that the metal fabrication landscape is in flux. The FAB40, a key gauge in the metal fabrication realm, has seen an upswing in investment and acquisition activities, especially in 2022. These initiatives aim to extend geographical reach, bolster capacity, and delve into fresh territories. This surge signifies metal fabricators' ardent pursuit of expansion and innovation.

However, amid the wealth of opportunities, challenges abound. Metal fabricators must continually upgrade their equipment and technology to stay competitive. Factors like fluctuating raw material prices and supply chain instability also warrant attention.

Why top metal fabricators are embracing laser technology

· Expanding capacity:

One compelling reason why leading metal fabricators are gravitating toward laser technology is its remarkable capacity expansion capabilities. Laser cutting and welding machines are renowned for their high-speed, high-efficiency performance, allowing swift order processing across various metal materials. This translates to the ability to handle more orders in less time, effortlessly meeting the surging market demands.

· Handling specialized materials:

Laser technology isn't limited to run-of-the-mill metals; it excels at handling specialty materials like aluminum alloys, brass, and copper. This empowers top metal fabricators to venture into upscale markets. With laser precision and control, they can craft components tailored to precise requirements, serving industries such as semiconductors and defense.

· Precision and heavy-duty processing:

Laser technology is a maestro when it comes to precision and heavy-duty tasks. It can effortlessly slice tiny components while also tackling the processing needs of hefty structures. This adaptability empowers top metal fabricators to broaden their business horizons, catering to diverse customer needs, whether it's crafting small parts or assembling large structures.

Opportunities and challenges for traditional metal fabricators

Traditional metal fabricators find themselves at a crossroads, replete with both opportunities and challenges. Market demand continues its upward trajectory, especially in burgeoning sectors like electric vehicle manufacturing and renewable energy. However, to remain competitive, they must perpetually upgrade their equipment and technology. Furthermore, the metal fabrication industry grapples with issues like volatile raw material prices and supply chain unpredictability, necessitating adaptable strategies.

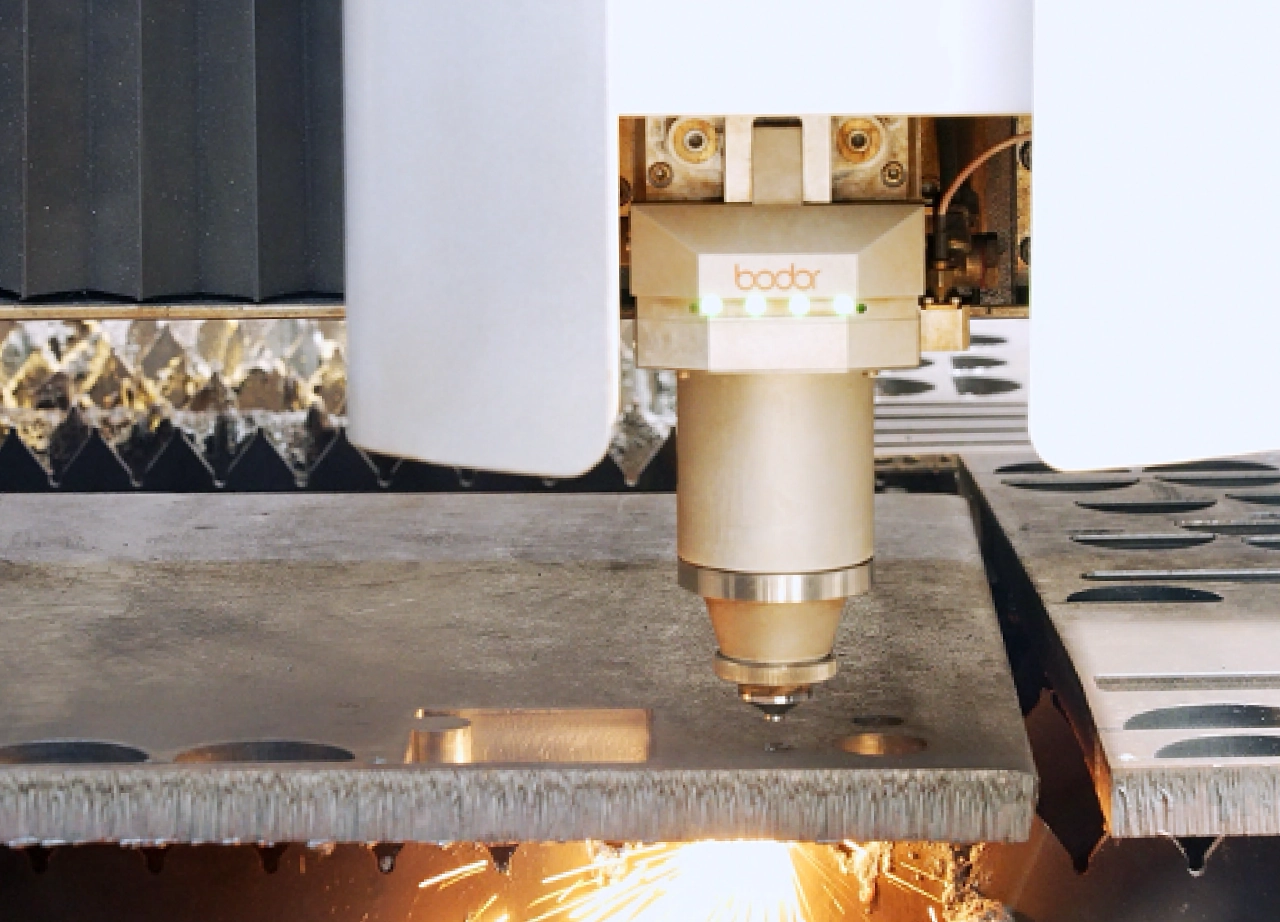

Bodor laser solutions

Bodor offers an array of high-performance laser cutting machines and handheld laser welding devices tailored to meet metal fabricators' needs. These solutions seamlessly blend cutting-edge laser technology with innovative design, bestowing a competitive edge upon metal fabricators. Laser cutting machines swiftly and efficiently cut through a variety of metal materials, while handheld laser welding machines provide high-quality and high-strength welding results suitable for specialty materials and precision work.

In conclusion

Laser technology has found favor with top metal fabricators due to its capacity expansion, prowess in handling specialized materials, precision, and ability to tackle heavy-duty tasks. These advantages enable metal fabricators to deftly navigate the surging market demands, securing their prominent positions in an intensely competitive industry. Laser technology is molding the future of the metal fabrication sector, and top metal fabricators are wholeheartedly embracing this transformation, ready to conquer a dynamic market.