Bodor Tech Blog

Trending and helpful laser knowledge for your success

Advantages of Using Laser Cutting Technology in Producing Agricultural Machinery

The manufacturing of agricultural machinery involves complex sheet metal components, placing high demands on processing technology. Sheet metal processing for agricultural machinery components typically involves steel plates under 20mm, which are widely varied and rapidly updated. However, traditional punching processes are not efficient for small-scale, single-item production.

Against the background of this challenge, laser technology has demonstrated its advantages. One of the world's largest agricultural machinery companies, John Deere, employs laser cutting technology to produce agricultural machinery and provide customers with high-quality products.

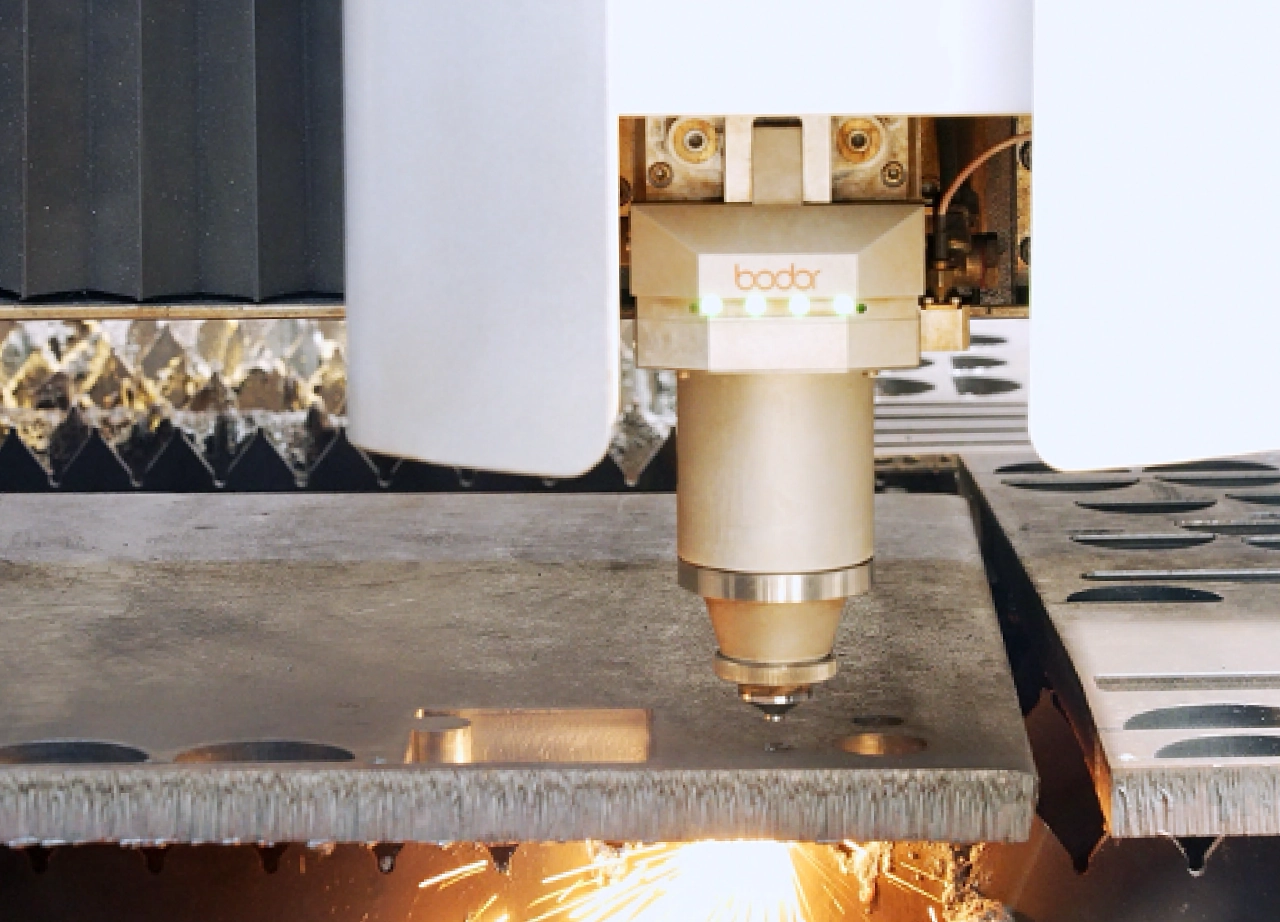

The primary working principle of laser cutters involves using a powerful laser beam to heat and change the shape of the material being cut. Laser cutting is suitable for making different parts because it is precise, high-quality, efficient, and affordable.

High precision and high quality

The demand for precision and quality in agricultural machinery components is exceedingly high. These components must endure harsh conditions while maintaining long-lasting durability. Traditional cutting processes for agricultural machinery components often encounter issues such as workpiece deformation.

Laser cutting employs a non-contact processing method, ensuring that the cutting process does not cause any damage to the surface of the workpiece. The high-penetrating narrow laser ensures high-precision cutting without changing the shape of the workpiece, creating smooth, shiny parts without burrs. Given that the precision assembly of agricultural machinery components is crucial during manufacturing, the high-precision advantage of laser cutting becomes particularly evident.

High efficiency

In mechanical machining, making tools and fixtures consumes a lot of time. Using a laser cutting machine to cut metal sheets for agricultural machinery offers faster cutting speeds. This technology allows for the one-time production and processing of products with different shapes and varying thicknesses, significantly reducing the production cycle and enhancing overall production efficiency.

Low cost

The application of laser cutting technology can significantly reduce raw material costs. Laser cutting machines are more cost-effective than traditional punching machines as they can optimize the nesting automatically. This helps to avoid creating lots of scrap material when cutting complex shapes like circles and arcs, which reduces waste.

Laser cutting also contributes to lowering labor costs. The CNC system can provide real-time feedback on processing status, automatically adjust control strategies, and reduce the need for manual intervention. The machines' operation is user-friendly, requiring operators to have minimal specialized experience, thus saving significant labor costs. Moreover, laser cutting machines can be equipped with various automation devices, enabling highly automated production.

Additionally, laser cutting machines have lower maintenance costs. Laser cutting machines typically have fewer moving parts than traditional methods like waterjet cutting. This means fewer components can wear out or break down, reducing the need for frequent maintenance. Besides, laser components have a long lifespan. With proper care and periodic servicing, the components will not have significant performance degradation, and the maintenance costs can be kept low over time.

Tailored solutions to meet customization needs

Laser cutting machines can process and manufacture flexible products, significantly reducing mold costs. The absence of mold constraints makes designing new products much more effortless. Through advanced control provided by the control system, the narrow laser beam enables precise cutting, producing various components that fully meet specific requirements. It effortlessly handles even the most intricate designs, catering to customization needs.

High material adaptability

Laser cutting machines can cut nearly all types of metal materials, including stainless steel, copper and aluminum. Laser scanning cutting, an innovative technology, makes the efficient batch processing of reflective metal materials possible. The laser cutting machine's power can be adjusted based on the material being processed, utilizing high power for thick metals and low power for precision cutting of thin materials.

Ensuring worker safety

Laser machines are safer compared to other machinery. They don't require any manual contact with the material being cut, significantly reducing the likelihood of accidents. In contrast, traditional punching processes generate high noise levels and strong vibrations, posing health hazards to operators. Laser cutting machines operate silently and without vibrations, ensuring worker health and safety.

Eco-friendly

Traditional cutting methods generate significant noise and produce large amounts of dust, causing noise and air pollution. In contrast, laser cutting machines operate with minimal noise and feature a follow-up zonal dust removal system that ensures real-time smoke extraction. This effectively addresses workshop dust pollution concerns and ensures industrial emissions comply with environmental standards.

Innovative technologies

In addition to the inherent superiority of laser cutting, advanced laser cutting machines are typically equipped with innovative technologies that further enhance the cutting process. Several leading laser solution providers worldwide have introduced numerous intelligent functions, such as the one-second edge finding, intelligent remnant layout, and excellent bevel cut functions of Bodor Laser. Such features can further enhance the processing precision, quality, efficiency, material utilization, etc.

In conclusion, the application of efficient and intelligent laser cutting machines is paramount in upgrading the process of agricultural machinery manufacturing. The continued innovation and implementation of such advanced technology will undoubtedly play a crucial role in meeting the growing demands of agriculture.

Contact us today to access customized laser cutting solutions and bring your production to the next level!